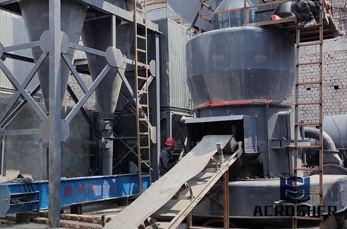

discussion of grinding machine Mine Equipments

Grinding machine Wikipedia, the free encyclopedia A grinding machine, often shortened to grinder, is any of various power tools or machine tools used for grinding, which is a .

WhatsApp)

WhatsApp)

Grinding machine Wikipedia, the free encyclopedia A grinding machine, often shortened to grinder, is any of various power tools or machine tools used for grinding, which is a .

TYPES OF GRINDING MACHINES From the simplest grinding machine to the most complex, grinding machines can be classified as utility grinding machines, cylindrical grinding machines. and surface grinding machines. The average machinist will be concerned mostly with floormounted and benchmounted utility grinding machines, bufting machines. and ...

Jan 03, 2019· Thread grinding machines: This is a type of special grinding machine having a special grinding wheel. This machine is almost similar with the cylindrical grinding machine but it has very precised lead screw for producing the accurate pitch on the threaded part. This machine is used to produce very fine threads after the grinding operation.

Select Carbide Case Studies. Glebar''s versatile precision grinding machines are workhorses which require a smaller footprint than similar machines yet excel in demanding high production environments where the name of the game is high volume at low cost, with exceptional precision.

Skip navigation Sign in. Search

A grain grinding machine is an equipment used for grinding maize, beans, melon, millet and such other good crops. This equipment comprises essentially of an electric motor, belt, pulley, transmission shaft, hopper, mills, spiral conveyor and stands.

Image courtesy of Wikipedia. If you''re looking to shape the outside of an object, cylindrical grinders are your target machine. The Ecotech cylindrical grinder is a high rigidity design for grinding small, medium and large size workpieces in single and lot size production.

The Mill Cincinnati Milling Machine Company led by of centerless grinding technology. Grinding Machine Types Parts Working. Grinding Machine Definition A grinding machine or grinder is an industrial power tool that uses an abrasive wheel for cutting or removing the m aterial..

– A machine operation in which a work part is fed past a rotating cylindrical tool with multiple edges. (milling machine) • Types – Peripheral milling • Slab, slotting, side and straddle milling • Up Milling (Conventional) down milling (Climb) – Facing milling • Conventional face, Partial face, End, Profile, Pocket contour ...

is a platform for academics to share research papers.

study of the grinding machine Solved A Grinding Machine Has A First Cost Of 24,000 Wit . home / study / business / economics / economics questions and answers / A Grinding Machine Has A First Cost Of 24,000 With An Expected Useful Life Of 13 Years.

Study of Machine Tools – Grinding Machines Page 3 Grinding machine operations The process of grinding is the operation of removing excess material from metal parts by a grinding

grinding machines perform the dressing task automatically. The application of coolants to the grinding process is important. Coolants reduce grinding machine power requirements, maintain work quality, stabilize part dimensions, and insure longer wheel life. Coolants are either emulsions, synthetic lubricants or special grinding oils.

discussion of grinding machine. Surface grinding Deeper cuts for better finishes Practical Apr 21 2007 In Response To surface Grinder depth of cut Len Tate i just came across this discussion because it was a link in another discussion either machine it down or if we do grind it we will take heavy cuts as described and the.

Dec 29, 2016· Grinding Machine (Parts And Functions) हिन्दी ... Unsubscribe from LEARN AND GROW? Cancel Unsubscribe. Working... Subscribe Subscribed ... Grinding Wheel most .

Grinding Machine Definition: A grinding machine or grinder is an industrial power tool that uses an abrasive wheel for cutting or removing the m aterial.. It is a process of metal cutting by using a rotating abrasive wheel from the surface of the workpiece.. Generally, the grinding is finishing operation to show the high surface quality, accuracy of the shape and dimension.

The global computer numerical control machines market size is expected to reach USD billion by 2025, registering a CAGR of % from 2019 to 2025, according to a new study by Grand View Research, Inc. The increasing need for reducing the operating costs, manpower, and errors in the components has led to the growth of automation and CNC machines

Apr 06, 2015· The size of a grinding machine is specified according to the size of the largest workpiece that can be mounted on the machine. The cylindrical centre type grinding machine is specified by the diameter and length of the largest workpiece the machine can accommodate between centers.

Grinding machines, like broaching machines, operate over a range of speeds depending on the type of machine being range from approximately 1250 to 2000m min −1, although in highspeed grinding speeds of up to 5400m/min are achievable (Schey, 1987).The two most common grinding applications are cylindrical grinding and surface grinding.

Grinding is a metal cutting operation like any other process of machining removing metal in comparatively smaller volume. The cutting tool used is an abrasive wheel having many numbers of cutting edges. The machine on which grinding the operation is performed is called a grinding machine. Grinding is done to obtain very high dimensional accuracy.

Apr 06, 2015· The process of grinding is the operation of removing excess material from metal parts by a grinding wheel made of hard abrasives. The following operations are generally performed in a grinding machine.

Oct 19, 2012· Article on grinding machine, types and uses of a grinding machine, manual surface grinder, manual surface grinding machine including hydraulic surface grinding machine, cylindrical grinder, cylindrical grinder machine, centerless grinding, centerless grinding machine for automobile, electronic, electrical and engineering industries by leading distributors of machine tools, Bhavya Machine .

Apr 06, 2015· The grinding wheel should be inspected and mounted on the spindle. Proper work speed, wheel speed and table feed should be selected according to the nature of the work. Safety goggles should be worn by the operator. It should be checked whether the safety guards are fitted. The operator should not touch the rotaing work or the grinding wheel.

Sep 23, 2017· in this video some important Question with Answer grinding machine. Trade for Fitter,Machinist, Turner, Grinder, etc. this spl. Question Exam paper for Ordnance factory, .

WhatsApp)

WhatsApp)