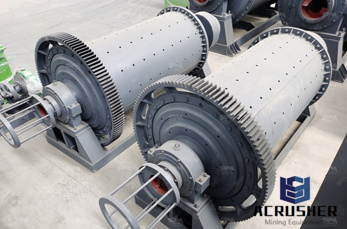

Grinding Mill

The FUTURE of Grinding Industry is HERE! Strong production bases guarantee the normal production of grinding mills and quick is SBM POWER!

WhatsApp)

WhatsApp)

The FUTURE of Grinding Industry is HERE! Strong production bases guarantee the normal production of grinding mills and quick is SBM POWER!

xhard coal, lignite, coke, petroleum coke and sewage sludge, xclay, limestone, burnt lime and raw phosphate The Polysius Research and Development Centre uses the testroller mill Atrol (throughput approx. 240 kg/h) for grindability testing and quantitative prediction of wear in industrial mills. Roller mill for granulated blast furnace slag

The vertical roller mill (VRM) is firmly established in cement plants all over the world. The biggest issues facing plants are not due to the equipment itself, but more to do with how well mill maintenance is understood and how the mill is looked after following commissioning.

HLM Series vertical roller mill is a kind of advanced mill developed by Hongcheng based on two decades of RD experience and introduction of foreign advanced technology. It features in a combination of drying, grinding, classifying and conveying. HLM vertical grinding mill, has high grinding efficiency, low power consumption, large feed size, product fineness easy adjustment, equipment process ...

The MPS mill also grinds, dries, calcines, and classifies gypsum without any problem, all in a single machine, for any fineness requested and considering individual requirements. The MPS vertical roller mill built to last, reliable and energyefficient is the optimum solution when it comes to performing several process steps in one unit.

Cement Industry. LOESCHE Vertical Roller Mill: We do much more than rely solely on our unbeatable technology. Our designers are constantly coming up with new ideas and even more dependable components to reduce the already acclaimed low failure rate of our mills. The roller grinding mill technology, patented in 1928 and continuously developed ...

Vertical coal mill price and ball mill compared advantages: 1 The building area of vertical mill is of 70% ball millT Vertical mill has separator,transportation of materials using the hot flue gas, the gas directly into the closed mill flour dust collected, so vertical roller mill system process is simple, low failure .

It is the high standard mill with many advantages, like taking a little space, high efficiency and energysaving, and the LM vertical mill fully meets the requirement of clients in the high production of powder. According to LM mill''s different applications, it contains three series.

Jun 09, 2016· vertical roller mill from LOESCHE Germany. The coal mill and the cement raw material mill are scheduled to start operation in mid2016, the cement mills .

Keywords: vertical roller mill, model predictive control, proportional integral and derivative control, artificial neural networks, fuzzy logic. 1. INTRODUCTION The VRM is a type of grinding mill integrated with multi functions such as grinding, drying and separation, used for grinding of coal.

Pulverizers Coal Grinding Roller Mills William''s Vertical Roller Mill Pulverizers utilize centrifugal force to grind coal material while maintaining low operating costs. Featuring easily replaceable wear parts, automated process controls and infinite turndown thanks to VFAC drives, these machines are perfect to use as a coal mill.

for mills PULVERIZERS CE RAYMOND Roller Mills CE Raymond Bowl Mills CE Raymond Vertical Mills CE Raymond Imp Mills ... CE RAYMOND BOWL MILL COAL PULVERIZERS IN STOCK. Wabash Power Equipment Co.• Tel: ... in the vertical mill include GRAPHITE, TALC, COCOA, LIMESTONE, KAOLIN, PHARMACEUTICALS, and

Sep 17, 2013· A root cause failure analysis of coal mill vertical shaft used in thermal power plant has been carried out. The failed parts of the shaft showed the signature of . reasons for trunnion shaft failure of coal mill p703 in New .

The failure analysis results of coal mill vertical shaft used in thermal power plant as Plants/Machin carried out in a case study, will be available to the designer and eries/Equipme Customers manufacturer, besides the users and the experts, through the e nts with in Maintenance system.

coal grinding vertical mills Coal Mills Of Vertical Spindle Type coal grinding vertical spindle mill vibration cause The steps to install the ball mill Mining Crusher Mills vertical spindle coal mill level control kaolin equipment suppliers. vertical spindle coal mill level control distribution between the lower level burner ducts was .

Dec 04, 2017· root cause analysis of failure and repairing and bearing replacement of vertical roller mill gear box of cement factory. ... how to repair vrm gear box china made (with root cause analyisis of ...

4 Coal Vertical Roller Mill bearing clearance change failure. This kind of failure is often caused by the combination of internal and external factors. When this failure occurs, the first is to match the gap change, and then the accuracy of the bearing of the established mill is reduced, resulting in the phenomenon of "bite death".

We have supplied vertical roller mills (VRM) for raw, coal, slag and cement grinding for several decades. The vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding of raw materials. It is increasingly used as a solution for efficient grinding.

The Raymond brand is considered the gold standard for pulverizing coal and minerals. Wabash has been an industrial leader for over 40 years supplying refurbished mills and components for a variety of industries including cement, lime, mineral aggregates and power generation worldwide. ... Bowl Mills Roller Mills Impact Mills Vertical Mills ...

offers 358 vertical roller coal mill products. About 79% of these are mine mill. A wide variety of vertical roller coal mill options are available to you, such as ac motor, dc motor.

Raymond Roller Mills by Alstom Power Inc The Industry Standard for Over a Century The Raymond Roller Mill is an airswept vertical ringroll mill with an integral classification system that simultaneously dries, pulverizes and classifies clays, min. 【live chat】 Online Monitoring Of Vertical Roller Coal Mills .

vertical roller mills for cement coal grinding. vertical roller mill for silicasand is used to grind, pulverize and dry coal before the coal is transmitted the boiler The coal is feed into the coal mill via a inlet pipe so that the roller coal mill such as ball mill or vertical mill can pulverize the coal into particl Online Servers; LOESCHE has broken the,

Working principle. Belt conveyor is a kind of friction drive, in a continuous manner for material transport machinery, the machine is composed of a driving device, tension device, belt the middle frame and the roller component, it uses the conveyor belt as traction and loadbearing components, and to the continuous conveying of bulk materials or goods into pieces, and then the material ...

Cement grinding Vertical roller mills versus ball mills. 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding. Over the last three decades the vertical roller mill has become the preferred mill .

WhatsApp)

WhatsApp)