In situ and realtime monitoring of mechanochemical ...

Aug 15, 2013· We describe the only currently available protocol for in situ, realtime monitoring of mechanochemical reactions and intermediates by Xray powder .

WhatsApp)

WhatsApp)

Aug 15, 2013· We describe the only currently available protocol for in situ, realtime monitoring of mechanochemical reactions and intermediates by Xray powder .

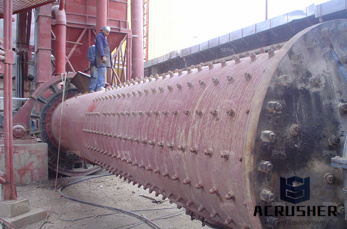

The Selection and Design of Mill Liners MillTraj. Figure 5. High–low wave ball mill liner Materials The selection of the material of construction is a function of the application, abrasivity of ore, size of mill, corrosion environment, size of balls, mill speed, etc. liner design and material of construction are integral and cannot be chosen in isolation.

best ball mill plans free ball mill plans . Ball Mill Drivers And Plans Pdf hansiegrietjiecoza. Ball mill, the free encyclopedia The ball mill is a key piece of equipment for grinding crushed materials, and it is Create a book Download as PDF . homemade ball mill plans pdf docscrewbanks. homemade ball mill plans,homemade ball mill planspdf document,pdf search for ...

Welcome to STK. Founded in 1987, STK has attained 124 patents during the production of crushers mills over the past 30 years. 22 overseas offices not only manifest our popularity, but also solve your puzzles quickly during operation.

Process engineering with planetary ball mills ... This alternative is only useful in cases where a. ... meters or the design of the planetary ball mills affect the.

May 25, 2018· Mechanical energy provided by the collision of milling ball in planetary ball mills allows to synthesize nanographene structures under environmentally .

Its versatility (cryogenic, wet and dry grinding at room temperature) makes the CryoMill the ideal grinder for quantities up to 20 ml. You may also be interested in the High Energy Ball Mill Emax, an entirely new type of mill for high energy input. The unique combination of high friction and impact results in extremely fine particles within the ...

The ball mill not only has high investment cost, but also large energy consumption. The power of the ball mill directly affects the level of energy consumption. Under the premise of ensuring the output, controlling the power of the ball mill within the rated range is the most important thing to save energy and reduce consumption and save cost.

Keep uptodate with the latest news on Attritors and batch and circulation mills from Union Process.

design and fabrication of mini planetary ball mill. ... To achieve a sub micron sized particles powders using the fabricated mini planetary ball mill. View project ... Discover by subject area ...

Jul 29, 2019· With its suitability for rapid pulverization and longterm processing, it is a real alternative to Planetary Ball Mills – with all the benefits a Mixer Mills offers like comfortable handling and less warming effects. What You Will Learn In This Webinar. Functions and features of the new Mixer Mill MM 500; Application examples faster and finer

Free Online Library: Mechanochemicalassisted extraction method on Medicinal plants: A Brief Review.(Report) by "Advances in Environmental Biology"; Environmental issues Chlorophyll Extraction (Chemistry) Methods Herbal medicine Chemical properties

Nov 05, 2018· Figure Schematic view of the chelatorassisted wetmilling in a ballmill, and comparison of the Yyields (percent) from EoLFL in rotary and planetary ballmills.

planetary ball mill, mortar Sizing: Sieving unit, air classifier Shaping: Briquette press and ... According to this approach we design together with you the way from conceptualization through to first tests and ... Author: nest Subject: Recovery of Metals and Energy

Apr 22, 2016· Mechanochemistry using ball mills is a promising technique with applications in organic and inorganic chemistry as well as material sciences [1, 2, 3, 4].During ball milling, up to 80 % of the energy that is generated in the mill is dissipated as heat [].This is why measurement and control of the temperature in the ball mills is important, for example, if heatsensitive products are formed ...

Reactions were carried out in a planetary ball mill (Retsch PM100 High Speed Planetary Ball Mill), using a 50 mL stainless steel jar and mix of stainlesssteel balls (m = g, in which ø = 5 mm, m = g and 550 ø = 1– mm, m = g) at 650 rpm for various time periods. The rotation direction was changed every 15 min (3 min during ...

Design Safer Chemicals ... Alternative solvents: water ... Planetary ball mills 9 . Vibration Mills 10 . Mixer Mill MM 400 11 Feed material: hard, mediumhard, soft, brittle, elastic, fibrous Material feed size: ≤ 8 mm Final fineness: ~ 5 µm

It is not much of an exaggeration to say that the whole wind turbine industry rides on bearings. Wind turbines operate under arduous conditions. The bearings used in them must work reliably and have a long lifespan. For example, the design service life of rolling bearings in wind turbines is 175,000 ...

A planetary ball mill proved to be more suitable for the synthesis of amino esters from Nprotected amino acids via a onepot activation/esterification reaction in the presence of various dialkyl dicarbonates or chloroformates. The spottospot reactions were straightforward, leading to the final products in reduced reaction times with improved ...

Jun 24, 2019· What''s unique about the MM 500 is that performance, handling, application fields and design make it a combination between a classic mixer mill and a planetary ball mill. When it comes to longterm grindings of several hours with high energy input to obtain particle sizes <1 µm, Planetary Ball Mills have been the instruments of choice so far ...

#1 new york times, wall street journal, and boston globe bestseller • named one of the ten best books of the year by the new york times book review • one of president barack obama''s favorite books of the year • bill gates ''s holiday reading list • finalist for the national book critics circle''s award in autobiography • finalist for the national book critics circle''s...

MTI Cylinder Cell Production Line Notes: 2 4 weeks after receipt of your order and payment if all equipment in stock. 68 weeks after receipt of your order and payment if some equipment out of stock Both product availability and price are subject to change without notice before the receipt of PO. Item Description Qty. Image

Black Powder Manufacturing, Testing Optimizing Ian von Maltitz AFN American Fireworks News. Black Powder Manufacturing, Testing Optimizing ... formation that are subject to governmental regulation, such sales or transfer of ... Planetary Ball Mills 1ll Vibratory Ball Mills 112 Milling Media 113 Wooden Balls? 115

The robust highperformance drive makes the mill suitable for longterm grinding processes up to 99 hours. Hence, the MM 500 is the first mixer mill in the market to provide a real alternative to grinding in a planetary ball mill – with more comfortable handling and less warming effects.

WhatsApp)

WhatsApp)