Vertical Mill Drills | Baileigh Industrial

Baileigh Industrial offers metal machinery and metal fabrication equipment. Look no further than Baileigh Industrial for you Fabricating Needs.

WhatsApp)

WhatsApp)

Baileigh Industrial offers metal machinery and metal fabrication equipment. Look no further than Baileigh Industrial for you Fabricating Needs.

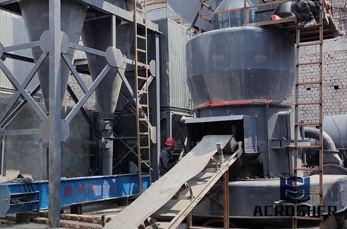

VMseries vertical mill is one advanced mill, adopting top technology domesic and abroad, and based on many years'' mill experiences. It can crush, dry, grind, and classify the materials. VM series vertical milling machine can be widely used in such industries as cement, power, metallurgy, chemical industry, nonmetallic mineral.

Hammer milling and grist storage technology under co2 boccard fine grinding carried out with a hammer mill and combined with the thin bed filter meura 2001 leads to the production of a clear wort with a low fatty acid,Vertical Hammer Mill Pdf Grinding Mill China.

JET Vertical Milling Machines are manufactured for precision, reliability and durability. Table sizes ranging from 8" x 36" to 12" x 54" and drivetrains of step pulley, variable speed, and electronic variable speed allow for easy mill selection.

Technical Notebook CEMENT ADDITIVES FOR VERTICAL MILLS 06 The different manufacturers of vertical mills mainly distinguish themselves in the shape of the grinding rollers and therefore the grinding plate''s profile. The dynamic separators are the same as the ones used on tubular ball mills, obviously adapted to the vertical grinding machinery.

Vertical roller mill is a kind of grinding machine for cement raw material, cement clinker, slag and coal slag. It has the features of simple structure, low cost of manufacture and use. Vertical roller mill has many different forms, but it works basically the same.

If your work requires both horizontal and vertical milling in a small footprint, this is the machine for you! Simple conversion to horizontal and vertical milling operations means there''s very little setup time. The DC motor also provides variable spindle speeds for matching material, tooling, and finish.

Vertical roller mills KTM Assembly of a mill for 150 t/h of raw meal With 4 runners in PSP''s work shop: Grinding runner with carrier Lift out of grinding runner Placement of grinding carrier in the bearings Cover of the grinding chamber Check assembly of the upper part of the mill separator Placement of grinding carrier in the bearings

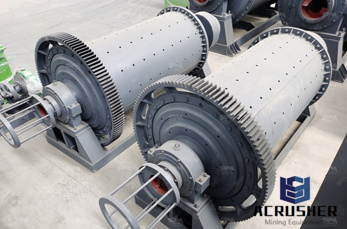

According to the ways by which motion is imparted to the charge, grinding mills are generally classified into two types: tumbling mills and stirred mills. In tumbling mills, the mill shell is rotated and motion is imparted to the charge via the mill shell. The grinding medium may be steel rods, balls, or rock itself.

today is the most used mill for cement grinding. Over the last three decades the vertical roller mill has become the preferred mill for grinding of raw materials. The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill

Tower mills, often called vertical mills, stirred mills or regrind mills, are a more efficient means of grinding material at smaller particle sizes, and can be used after ball mills in a grinding process. Like ball mills, grinding (steel) balls or pebbles are often added to stirred mills to help grind ore, however these mills contain a large ...

Nov 06, 2013· ''s VERTIMILL Vertical Grinding Mill can bring up to 40% savings in energy consumption compared to more traditional grinding mills while enabling excellent recovery rates in .

When the flow transfers upwards, it passes all consecutive grinding stages. The final product discharges into open atmosphere at the top of the machine. Because of the tall and narrow vertical mill body arrangement, grinding media is evenly distributed and mineral particles remain in constant contact, significantly increasing grinding efficiency.

Vertical roller mill Vertical roller mill Vertical roller mill Vertical roller mill Vertical roller mill Vertical roller mill Main technical parameters of Vertical roller mill ( grinding mill ) Specification Capacity(t/h) Humidity of Raw Coal Fineness of Powder Humidity of Powder(%) Motor Power(kw)

Vertical mills Flexible mills with integrated separator. The vertical mill enables high energy economy, and convinces with low specific wear values. Drying of the feed material, grinding, separating, and material transport take place inside the mill. It is thus especially well suited for grinding products with high proportions of wet components.

Horizontal Mills. In contrast to vertical mills, horizontal mills have certain characteristics that are better suited to wet grinding. A horizontal mill is generally made up of a horizontal tubular grinding chamber, in the center of which is an agitator shaft with agitator disks. Energy is transferred from the disk to the fluid in the mill and ...

The same Vertical Rotary Grinder is an economical method for finish sizing large steel plates, metal fabrications, and castings ead of surface grinding and CNC milling for large plate finishing. Vertical rotary grinding multiple small parts in batches results in consistent thickness and surface finish, eliminating mismatches.

It is capable of handling feed sizes up to 6 mm and grinding to products less than 20 microns, and has standard mill sizes ranging from 15HP (11kW) to 4500HP (3352 kW). Support from experts. draws from more than 100 years of mill design and manufacturing expertise, and over three decades of successful Vertimill® applications.

We have supplied vertical roller mills (VRM) for raw, coal, slag and cement grinding for several decades. The vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding of raw materials. It is increasingly used as a solution for efficient grinding.

Grinding Equipment. HCH Ultrafine Grinding Mill for Preparation of Petroleum Coke Powders HCH Ultrafine Grinding Mill for Preparation of Petroleum Coke Powders ; The Process of Special HLM Superfine Vertical Grinding Mill for the Factory of Slag Powder The Process of Special HLM Superfine Vertical Grinding Mill for the Factory of Slag Powder

Vertical roller mill pdf in we have livechat to answer you vertical grinding roller mill pdf download vertical roller mill gear box manual in pdf format principles of the vertical mill pdf for chemical grinding mill mill wiring diagram free pdf files cement grinding vertical roller mills versus applications of the vertical roller mill.

Vertical Mill Grinding Principle Pdf Jaw crusher ball mill When the mill is starting and stopping the grinding force is reduced by lowering the hydraulic . Largescale crushing screening milling plants. Offer efficient, costeffective services for you. +7(927)687 07 58 [email protected]

We are specialized in manufacturing vertical grinder, such as vertical grinding. Chevalier has years of vertical grinder development and manufacturing experience, in order to science and technology innovation, good faith, service business philosophy in close cooperation with old and new customers, grow together, common development.

VERTICAL MILLS IMP MILLS The imp mill is extensively used for processing and pulverizing of many materials. Typical grinding applications include CLAY, GYPSUM, KAOLIN, TALC, PIGMENTS, STARCHES, LIME PRODUCTS, OXIDES, INSECTICIDES LITHARGE. Available capacity size range: 2,000#/hr. (#10) to 20,000 #/hr.(#63). VERTICAL MILLS These mills are ...

WhatsApp)

WhatsApp)