Manufacture of Portland Cement Materials and Process

THE CEMENT MANUFACTURING PROCESS

WhatsApp)

WhatsApp)

THE CEMENT MANUFACTURING PROCESS

Moreover, the Company also received the Green Industry Level 5 (Green Network) Award for all of its plants, which is the highest award provided by the Ministry of Industry. This makes SCCC the first Company in the Thai cement industry awarded with Green Industry Level 5 certification for all of its cement manufacturing facilities.

For details about Basic Process of Cement Manufacturing, refer toCement Manufacturing Process

Ashoka''s cement plant unit has continued focused on objectives of product improvement and quality. In our entire turnkey cement plant equipments and machinery, we supply a complete assembly consisting of different machines and equipment, which facilitate the plant to execute efficiently and manufacture a betterquality completed product as per the international quality standards.

Sep 14, 2014· How make 2 gypsum tiles in 4 minutes | cement craft ideas | diy cement craft | creative cement ideas Duration: 4:09. DIY GYPSUM GYPSUM BOARD Recommended for you

Oct 03, 2016· For over 50 years, Lafarge cement has been part of Nova Scotia''s foundation. Each year, we produce 200,000 tonnes of cement at our Brookfield plant. Here is an overview of the manufacturing ...

From crisp packets to concrete buildings: the European Cement Industry demonstrates how everyday waste fuels cement manufacturing CEMBUREAU''s response to The Guardian''s ''Concrete Week'' Eurelectric and Energyintensive industries call for an ambitious and comprehensive EU Industrial Strategy to enable industry''s contribution to the EU ...

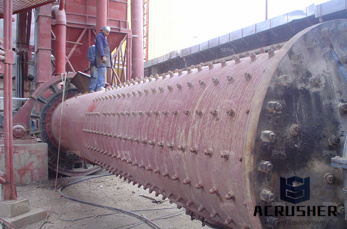

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc.. For information on materials, including reactions in the kiln, see the '' Clinker '' pages.

Jun 10, 2014· Cement manufacturing process 1. is cement ? of Cement Manufacturing process. of Kiln process. burn wastes ? 2. Portland Cement . A hydraulic cement made by finely powderising the clinker produced by calcining to incipient fusion a mixture of argillaceous and calcareous materials. .

Oct 29, 2019· Different manufacturing techniques will use either wet or dry grinding, but each cement manufacturing process will culminate in heating and fine grinding to finish the product. Preparing the raw materials is often the first step in the cement manufacturing process, and involves mining the limestone or obtaining safe industrial waste products.

Portland Cement . Cement: is a material with adhesive and cohesive properties which make it capable of bonding minerals fragments into a compact whole. For constructional purposes, the meaning of the term "cement" is restricted to the bonding materials used with stones, sand, bricks, building stones, etc.

The cement industry in the United States produced million tonnes (81,500,000 long tons; 91,300,000 short tons) of cement in 2015, worth US billion, and was used to manufacture concrete worth about US50 billion. The US was the world''s thirdlargest producer of cement.

ment as portland cement concrete, producing geopolymer cement concrete in a typical precasting facility is feasible. However, some of the unique characteristics of geopolymer cement concrete would necessitate changes in the process before scaling up production from bench scale to plant scale. The experience of manufacturing the

Cement history. Throughout history, cementing materials have played a vital role and were used widely in the ancient world. The Egyptians used calcined gypsum as a cement and the Greeks and Romans used lime made by heating limestone and added sand to make mortar, with coarser stones for concrete.

The 5 th International exhibition for the ASIAN concrete sector, the industry can look forward to seeing the latest in concrete, concrete surfaces, decorative concrete, material handling, concrete production, cement, building materials, construction equipment machinery with the latest technologies and techniques to sustain and grow their business.

Portland cement can be made by following two different processes – a dry one and a wet one. Joseph Aspdin first made portland cement in his kitchen stove in England in the 19th century. Lime and silica make up approximately 85% of portland cement. The materials that are commonly used are limestone, shells, chalk, shale, clay, slate, silica sand, and iron ore. Since limestone is the main ...

SHERA Public Company Limited, based in Thailand, has been established for over 40 years and is one of the largest manufacturers of fibre cement boards, siding and roofing and concrete roof tiles in the world.. SHERA''s range of fibre cement building materials are .

Accurate cement production also depends on belt scale systems to monitor output and inventory or regulate product loadout, as well as tramp metal detectors to protect equipment and keep the operation running smoothly. The Cement Manufacturing Process flow chart sums up where in the process each type of technology is making a difference. NOTE:

The global white cement market reached a value of US Billion in 2018, registering a CAGR of % during . The market value is further projected to reach US Billion by 2024, growing at a CAGR of % during .

Sep 18, 2019· Asia Cement Public Company Limited was awarded the certificate on lessening or avoiding greenhouse gas emission (Carbon Label) as well as the plate from Thailand Environment Institute as the entrepreneur having been awarded Carbon Label for 9 consecutive years.

Cement Cement Extraction and processing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary. Some deposits are mined by underground methods. Softer rocks such as chalk and clay can be dug directly by excavators. The excavated materials are transported ...

Thailand''s First Smart Connected Factory Driving growth in an emerging ASEAN economy Fujitsu has been helping the Siam City Cement Public Company Limited (SCCC) and its ITC subsidiary, INSEE Digital Company Limited to accelerate digital transformation for years. An example of this partnership is ...

Cement manufacturing process what is cement made of, it can be discussed conveniently under two headings: Selection of Raw materials and manufacturing methods. Raw Materials of Cement. Most important raw materials (what is cement made of) required in the manufacture of Portland Cement are: Limestone, Clay, Gypsum, Fuel, and Water (in wet method).

Portland Cement Manufacturing Process Description17 Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates, aluminates and aluminoferrites. More than 30 raw materials are known to be used in the manufacture of portland cement, and these

WhatsApp)

WhatsApp)