Slag powder production process YouTube

Jul 26, 2018· This video is unavailable. Watch Queue Queue. Watch Queue Queue

WhatsApp)

WhatsApp)

Jul 26, 2018· This video is unavailable. Watch Queue Queue. Watch Queue Queue

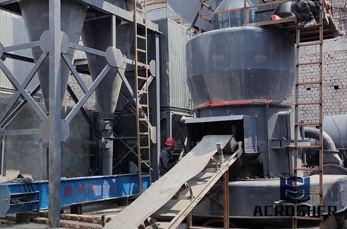

In the cement manufacturing production process, the slag is used as raw material to realize the recycling of waste and reduce the pollution of the slag to the environment. The vertical mill is mainly used as the main grinding equipment in the slag production line.

The general introduction of the technology used in the slag powder/steel slag powder production line with annual capacit. Cement Grinding Plant. Cement Production Line. New Type Dry Process Cement Production Line. 1500 Tons/Day Cement Processing Line.

Slag Powder Production Line Material development prospects. 1. Slag powder is widely used in engineering construction. It can replace 10~40% cement when concrete is placed. The strength of concrete can reach C60 or above, which can improve the life of concrete, increase its strength and reduce the construction cost. 2.

Production Fineness: S95. Zincgermanium slag and matte slag can be used to recover metals. (2) Slag powder supply to cement plant or mixing station . Production Fineness: S105. Steel slag, water slag, manganese slag, nickeliron and coal slag can be used as admixtures for concrete mixing station after grinding. The Main Uses:

CHAENG is the worldclass slag grinding system integrated service supplier, specially providing the "turnkey" service of daily output of 20120 tons of slag powder production line, steel slag powder production line and nickel slag powder production line for customers in china and abroad. Currently, CHAENG has own more than 100 projects of slag powder/ steel slag powder/ nickel slag powder ...

GGBS Production Line. Blast Furnace Slag Capacity: (t/h) Cement Capacity: 350(t/h) Raw Material Capacity: 6110(t/h) Groundgranulated blastfurnace slag (GGBS or GGBFS) is obtained by quenching molten iron slag (a byproduct of iron and steelmaking) from a blast furnace in water or steam, to produce a glassy, granular product that is then dried and ground into a fine ...

Apr 22, 2015· Slag powder production line last have a finished product warehouse, finished the slag powder is transported through the screw conveyor over, you can have the package delivered to require manufacturers of. Last August, Shanghai Baosteel and Xinxiang Great Wall machinery co., ...

CHAENG steel slag powder production line helps steel mills waste residue development and utilization News Date: 16:20:04. Steel slag is the solid waste discharged by steel mills during the smelting of crude steel, reasonable use of steel slag can play a role in protecting the environment, increasing economic benefits, and sustainable development of resources, and it has important ...

Slag Powder Line, Find Complete Details about Slag Powder Line,Slag Powder Line,Slag Powder Line Cost,Slag Powder Line Manufacture from Supplier or .

Superfine slag powder is a superfine powder with the gain slag of the blast furnace as the raw materials gained after crushing, drying and grinding. Its composition is very close to that of the cement, and it has very high activity, so that it is good mixing materials for cement and concrete and is a new type of green building material.

Steel Slag Crushing Plant Production Line For Sale: Steel slag crushing plant production line will be used to get fine size slag materials with high efficient. This line is composed with main powder grinding machine and the other equipment. As a professional manufacturer of mineral ore production line machine, SBM has designed the whole line of ...

Jul 04, 2018· CHAENG can undertake EPC turnkey services for slag / steel slag / nickel slag / manganese slag powder production line with an annual output of 200,0001,500,000 tons. slag powder production line. So far, CHAENG has established successfully more than 100 slag production lines in the world.

GGBS Production Line Features As a new type of high performance concrete admixture, slag (slag product applications) powder has all kinds of performance advantages about improving concrete compressive resistance, tensile resistance, sheared resistance and bended present, with the same amount of slag powder instead of concrete and cement product of cement dosage, which .

Superfine slag powder production line is also called ultrafine slag micro powder plant or superfine slag powder making plant. Superfine slag powder production line is used to crush non flammable materials of which Mohs hardness is no more than seven degree and water content is less than 6%.

1. Slag Powder We are a specialized suppler of slag powder production line. The slag powder is a kind of superfine powder grinded out of the blast furnace slag that is cooled rapidly in the water. Its chemical component includes the SiO2, Al2O3, CaO, MgO, Fe2O3, TiO2, MnO2 and so on.

Slag Grinding Plant. CHAENG can undertake EPC turnkey services for slag / steel slag / nickel slag / manganese slag powder production line with an annual output of 200,0001,500,000 tons.

Tons / Year Slag Micro Powder Production Line Pengfei Group provides the complete project plan of this tons/year slag powder production line. Cement Rotary Kiln As the main equipment in both of the cement clinker dry and wet process production lines; 1000t/d Active Lime Production Line

Slag Grinding Plant CHAENG (Great Wall Machinery) can undertake 20 tons million tons of Blast furnace slag/Steel slag/Nickel slag/Manganese slag powder production EPC projects. Up to now, CHAENG has constructed more than 100 slag grinding production lines at home and a

Slag powder production line. The production process of theSlag Powder Production Line(ggbs production line/ ggbfs production line) can be included as : (storage) >vibrating feeder >jaw crusher>impact crusher >vibrating screen >final products .And all of the machines are connected by the belt conveyor and chutes.

The Great Wall machinery is a professional supplier of slag powder production line, can provide "turnkey" service from civil engineering to debugging and capacity and standard reaching to customers, let customers put into production of mineral powder with saving worry, saving effort and highefficiency.

The vertical mill used in the production line of dry water slag powder is promoting resource recycli. water slag powder vertical mill adopts reasonable and reliable structure design,with advanced technological process,it combines drying, grinding,classifying,elevating in one system, especially in large slag grinding process,it can meet customer ...

We are a specialized suppler of slag powder production line. The slag powder is a kind of superfine powder grinded out of the blast furnace slag that is cooled rapidly in the water. grinding mill series reach the fineness of up to 51500 micron. There are many different types of grinding mills and many types of materials processed by them.

grinding production line:utral fine powder mill . and case. Ball mill grinding production line. Material after broken jaw crusher by bucket elevator sent to the storage bin, through the electromagnetic vibrating feeder grinding materials uniform, quantitative, and continuously to the grinding powder main body, after ...

WhatsApp)

WhatsApp)