Ball bar testing YouTube

Jul 13, 2016· To guarantee optimum performance and motion accuracy, we perform multiple tests on each and every machine that leaves our production facility. These test will examine the motion of .

WhatsApp)

WhatsApp)

Jul 13, 2016· To guarantee optimum performance and motion accuracy, we perform multiple tests on each and every machine that leaves our production facility. These test will examine the motion of .

Harvey Tool is the leader in Specialty Carbide End Mills, Cutting Tools, Technical Expertise and Innovation to the metal working industry. Over 21,000 Tools. In Stock. Same Day Shipping.

Renishaw Ballbar Test Plot Interpretation Mills Page 2 of 24 pages. Positive Backlash in the Y Axis Type of backlash: Positive = Lost motion In this example, the YAxis lost motion is at the ... • The ball may be moving on the holding cup. Corrective Action:Inspect the ballbar hardware and do the test again. The plot has three distinct ...

Calculate the Speeds and Feeds of Carbide End Mills, Diamond End Mills, and Plastic Cutting Carbide End Mills with these General Machining Guidelines

Longball Sports Pub Grill 100 Indian Lake Ave., Gravois Mills, Missouri 65037 Rated based on 5 Reviews "Ate there for the first time yesterday...

Mar 11, 2013· I''ve never used a ball end mill before, but it seems like the numbers should be much higher since the overall material removed per pass is much less than a standard end mill. I''ve tried searching on Google and there doesn''t seem to be too many resources specific to ball end mills.

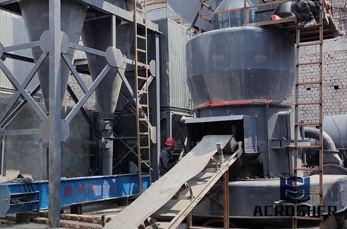

Solutions range from crushers, shredders and granulators, to hammer, ball and pin mills, air classifier or jet mills, colloid and corundum mills, just to name a few. This may be because the complexity of food milling applications varies significantly.

Metallurgical ContentOptimize Ball Mill Liner ReplacementLorain Shell LinersMill HEAD LINERSMill LINER BOLTSEffect of Liner Design on Mill Performance There are many different designs and styles of ball mill liners. As with grinding balls local economics and ultimately operating costs determine the best design and material to use. The initial set of liners is rarely the final design selected ...

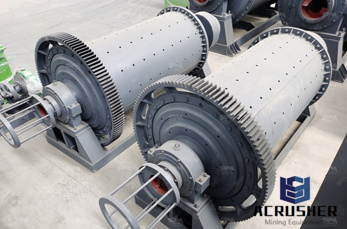

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles and stainless steel balls.

Jul 13, 2016· To guarantee optimum performance and motion accuracy, we perform multiple tests on each and every machine that leaves our production facility. These test will examine the motion of the CNC as well ...

Ballbar 5 Plot analysis and ballbar: Explanation of Ballbar plots and typical repairs actions to take; Axis reversal spikes. When an axis is being driven in one direction and then has to reverse and move in the opposite direction, instead of reversing smoothly it may pause momentarily at the turnaround point.

Jun 20, 2015· Besides dissipating a significant fraction of the total energy consumed by the mill (for example, the outer row of 50 mm diameter balls in a 4 meter diameter mill consumes close to one tenth of ...

13 reviews of Red Mills Pub "I was in the neighborhood after dropping my daughter off nearby for a sports dinner. Well, dinner time it is, so I met some friends here! After some debate, I ordered the BBQ Beef burger/sandwich. So you have meat,.

Ball Screw FAQs; Digital Readout FAQs; Videos. Sherline Videos; Instructional Videos; MASSO Videos; Test Cuts; Sherline Customer Videos; Sherline Blog; Dealers. Authorized Sherline Dealers; Authorized Sherline Worldwide Dealers; Authorized Sherline CNC Dealers; How to Become a Sherline Dealer; Product Line; LATHES. MILLS.

Block mills. Using a block mill, which drives multiple rolling mills and has been used on 100m/s class wire rod lines, as the bar steel finishing mill, will achieve speeds far beyond the finishing speed of about 20m/s that was the limit of conventional mills.

Mills first took up basketball as a fouryearold for a local Indigenous club his parents established called "The Shadows". Growing up, he was the ball boy for the .

Graffiti Bar and Kitchen 2a 2b Ball Street, S3 8 Sheffield Rated based on 4 Reviews "A little bit of Soho in the heart of Kelham, really...

Ball Mills Steel Ball Mills Lined Ball Mills. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800''s. The basic construction of a ball mill is a cylindrical container with journals at its axis.

The Les Mills SMARTBAND™ is a durable and functional resistance band. This new innovation in resistance band technology is scientificallyengineered to deliver a consistent force increase throughout the extension range. Made from injection moulded thermoplastic elastomer, the SMARTBAND eclipse traditional latex/rubber bands that are prone to ...

Cylindrical Ball Mills. The only cylindrical ball mills in common use are those of the grate discharge type, the most important being the Marcy and the AllisChalmers mills. Fig. 10 illustrates the construction of the Marcy Ball Mill. The cylindrical shell and the feed and discharge heads are made of cast semisteel.

Home > Milling > Indexable Milling > Indexable Mills > End Mills > Ball Nose View Filters. Filter Your Results. Applications. Channeling (45) Contouring (66) Coolant Thru (59) Helical / Corkscrew (66) Plunging (12) Pocketing (66) Ramping (66) Shoulder (12) Cutting Dia. Apply Range.

A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls – expressed as a percentage of the net internal mill volume (inside liners). B) Overflow Discharge Mills operating at low ball fillings – slurry may accumulate on top of the ball charge; causing, the Total Charge Filling Level to be ...

In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment.

This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder. The cylindrical jar is used as a mill that would rotate the ...

WhatsApp)

WhatsApp)