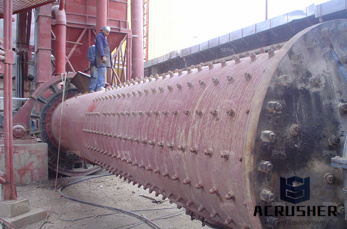

Raw Mill,Raw Mill In Cement Plant

Raw Mill Is Widely Used In Cement Plant. Raw mill is the key equipment for secondary grinding after crushing. And it is suitable for grinding all kinds of ores and .

WhatsApp)

WhatsApp)

Raw Mill Is Widely Used In Cement Plant. Raw mill is the key equipment for secondary grinding after crushing. And it is suitable for grinding all kinds of ores and .

Process control optimization of rotary kiln line, raw mill and coal mill at the Adana cement plant in Turkey 20% decrease in standard deviation, 10% longer refractory life, % energy saving, % production increase ... Reducing cement plant energy consumption and improving process control with ABB drives at Jura Cement in Switzerland.

Feb 23, 2016· Raw mill fans: Raw mill fan in cement industry carries gas and raw meal. The pressure drop in raw mill fan is very high. If a vertical roller mill is used for raw grinding in cement industry then a large raw mill fan is installed. Usually cement industries use centrifugal fans to carry out this process. 4.

• cement industry: Nghi Son, Vietnam, 1998,Guangzhou, China, 2005. Loesche developed the 4roller coal grinding mill with four tried and tested modules for throughputs over 150 t/h. The development was first realised in 1970 for grinding mills in the cement industry. This number of rollers also enables operation with only one pair

The reason for this is that at the very high temperatures in the kiln, many chemical components in the raw ingredients are burned off and replaced with oxygen from the air. Table lists just some of the many possible raw ingredients that can be used to provide each of the main cement elements.

with appropriate chemical and physical properties. Cement raw materials are received with an initial moisture content varying from 1 to more than 50 percent. For the Carolinas Cement Plant, grinding of blended raw materials occurs in an inline raw mill in which kiln exhaust gases are used to heat and dry the raw materials.

When it comes to achieving the best energy consumption, what are the key factors a cement producer needs to address? In this article, extracted from the newly published Cement Plant Environmental Handbook (Second Edition), Lawrie Evans presents a masterclass in understanding and optimising cement plant energy consumption.

MVR vertical roller mill from Gebr. Pfeiffer with patented multiple drive system MultiDrive® for the highest throughput rates and permanent plant availability Cement mills and raw mills .

vertical raw mill cement industry in uae; horizontal raw mill in cement plant; raw mill pressure drop reduction with external material circulation; cement plant vertical raw mill german made; raw gold grinder in south africa; what is raw mill in cement line; vertical raw mill animation in flv; raw material mill machine principle; crushing ...

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc.. For information on materials, including reactions in the kiln, see the '' Clinker '' pages.

Raw Mill In Cement Plant Ime Emeraldtechnology. Raw mill for cement plant images manveesinghement extraction and processing raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary. Get Price

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

4 Due to the interaction of raw materials and kiln gases, rotary kiln systems have inherent SO2 removal efficiencies ranging between 4099% of the sulfur input to the system. The literature suggests that 5070% of the remaining SO2 will be removed from exhaust gases when passed through an inline raw mill .

Each CAD and any associated text, image or data is in no way sponsored by or affiliated with any company, organization or realworld item, product, or good it may purport to portray. The GrabCAD Library offers millions of free CAD designs, CAD files, and 3D models. Join the GrabCAD Community today to gain access and download!

Mar 10, 2017· What is raw mill feed | how raw mill feed works in a cement industry? Working of raw mill feeder in cement plant is described here. Mechanical Engineering point of view about this raw mill feeder ...

The raw mix is fed into a circular storage unit called a raw mix storage. Then, the mix is extracted transversely from the stockpile by reclaimers and conveyed to a raw mill bin called the raw mix bin for grinding. The other raw materials that are used in cement manufacturing, called additives, are high purity limestone, sand and iron ore.

We supply all the fans for a complete cement plant. These include the process critical fans, mainly centrifugal, for the preheater exhaust, kiln induced draught, raw mill exhaust, final exhaust, cooler forced draught and cement mill exhaust applications. We also supply all .

re RAW MIX CALCULATION. HOW TO DESIGN A RAW MIX WITH EXPECTED ONE DAY STRENGTH OF CEMENT ? In order to design raw mix with expected one day strength of cement you must know statistic of testing calculate it in special programs such STATISTICA, SPSS take regression equation.

Mercury emission levels from two cement plants are contrasting. • Hg input and circulation determined the atmospheric emission levels. • Short term (several months) operation result in most Hg retained inside the production system. • Operation mode (on or off) of raw mill at kiln tail has obvious impact on Hg concentration and speciation.

Raw mill for cement plant images manveesingh cement extraction and processing raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary. Get Price;

The raw mix burns at 1500 °C producing clinker which, when it leaves the kiln, is rapidly cooled with air fans. So, the raw mix is burnt to produce clinker : the basic material needed to make cement. conveyor Next Raw mix kiln cooling Back preheating clinker storage at the plant Raw mill THE CEMENT MANUFACTURING PROCESS : The ...

Raw Mix Preparation Raw Mix Optimization Raw Mill Optimization ... the cement plants to achieve their desired quality, cost and safety targets. Online Measurement Composition Control ... material proportions in the raw mill feed. As in the former module, Model Based Control techno

Aug 30, 2012· Raw materials are extracted from the quarry and by means of conveyor belt material is transported to the cement plant. There are also various other raw materials used for cement manufacturing. For example shale, fly ash, mill scale and bauxite. These raw materials are directly brought from other sources because of small requirements.

Process Attendant Job at American Cement Company, LLC in ... Apr 11, 2016 ... Walk through raw mill grinding circuit and check for equipment ... Ensure the highest regard and practice of plant safety policies and procedures. ... met by an employee to successfully perform the essential functions of this job.

WhatsApp)

WhatsApp)