FL Advanced Filtration Technologies YouTube

Nov 21, 2017· FL has been a leading supplier of the global cement and minerals industry since 1882. But did you know that since 2000 we have been manufacturing our line of filter bags too? FL AFT ...

WhatsApp)

WhatsApp)

Nov 21, 2017· FL has been a leading supplier of the global cement and minerals industry since 1882. But did you know that since 2000 we have been manufacturing our line of filter bags too? FL AFT ...

Corn wetmilling is a process of breaking corn kernels into their component parts: corn oil, protein, corn starch, and uses water and a series of steps .

Engineering process and cost model for a conventional corn wet milling facility Article in Industrial Crops and Products 27(1) · January 2008 with 1,938 Reads How we measure ''reads''

May 16, 2016· This is usually accomplished economically on a rotary drum filter with belt discharge. DorrOliver Eimco EBelt Drum Filter DorrOliver Eimco EBelt Drum Filters for corn wet milling applications have been adapted to meet the industry''s specific .

THE HISTORY OF DORROLIVER . DorrOliver began at the turn of the 20th century as two oneman operations, backed by single patents for equipment developed to solve processing difficulties in gold milling.

EPA450/375054 October 1974 EMISSION FACTOR DEVELOPMENT FOR THE FEED AND GRAIN INDUSTRY ENVIRONMENTAL PROTECTION AGENCY Office of Air ami Wasle Management Office of Air Quality Planning and Standards Research Triangle Park, North Carolina 27711

corn industry and how it has played an integral role in the history of the wet milling industry. I am privileged to take part in this celebration of an organization that has supported the industry through a vastly changing and challenging landscape — from helping navigate trade relationships

Feb 03, 2015· Corn milling plant Email:sales ... कॉर्न फलैक्स बनाने का बिज़नस।Corn Flakes making business ... Food Industry Machines That Are ...

offers 843 corn wet milling machine products. such as free samples. There are 837 corn wet milling machine suppliers, mainly located in Asia. The top supplying country or region is China, which supply of corn wet milling machine respectively. Corn wet milling machine products are most popular in Africa, Southeast Asia, and Mid ...

Sefar filters for rotary drum vacuum filters. Rotary drum and vacuum filters are used in starch and gluten dewatering processes and in the polishing process of syrup as a socalled precoating filtration. Sefar has great experience in the optimization of filtration processes in the corn wet milling industry.

Discover all the products from FL DorrOliver Eimco and see a list of their distributors. Contact the manufacturer directly for a quote.

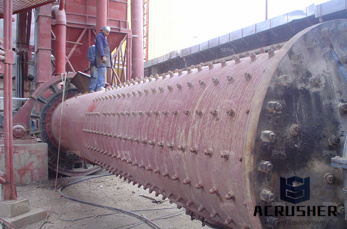

Rotary vacuum drum filter. Rotary vacuum drum filter (RVDF), patented in 1872, is one of the oldest filters used in the industrial liquidsolids separation. It offers a wide range of industrial processing flow sheets and provides a flexible application of dewatering, washing and/or clarification.

Many corn wetmilling plants want to increase production capacity, Corn gluten dewatering but are challenged by limited floor space. Solve the problem by switching from rotary vacuum drum filters to decanter centrifuges in the gluten dewatering process. This substantially frees up production space, and reduces energy consumption for subsequent ...

Corn deep processing is a big trend for grain oil development. Many investors are interested in corn processing industry, thus, it is necessary to have a good knowledge of its processing can be divided into dry and wet milling.

Corn wet milling is an extremely large but relatively little known industry. It is where corn is processed into vital products, of which the four principal ones are corn oil, starch, fructose, and animal feed. Facilities are located in dozens of corngrowing nations around the world.

ADVANCES I FOOD AND NUTIUTION RESEARCH,VOL. 38 N CORN WET MILLING: SEPARATION CHEMISTRY AND TECHNOLOGY DAVID S. JACKSON AND DONALD L. SHANDERA, JR. Department of Food Science and Technology University of NebraskaLincoln Lincoln, Nebraska 68583 I. Introduction A. Basic Process and Products B. Industry Scale 11. Corn: Structure and Types Used 111.

were operating 14 wetmilling plants in 1950. They used about 6 percent of our corn crop, or 140 million bushels. Three of the plants have occasionally wet milled grain besorghums since about 1945. Another firm method,has announced plans for wet milling about 2 million bushels (56,000 washingtons) of grain sorghum annually.

Corn Wet Milling Corn Wet Milling Corn Wet Milling Corn Wet Milling Corn Wet Milling COMPANY Equipment and Systems for Starch Processing DORROLIVER EIMCO Subscribe to view the full document. Steeping, Dewatering and Germ Washing 2 The process: Dewatering and Germ Washing Economical corn wet milling practice requires dewatering of the supply ...

filtration processes in the corn wet milling industry. Our experts will work to ensure that your final filter product is of the highest quality and performance. Starch and gluten dewatering Rotary drum vacuum filter equipped with Sefar filter media for starch dewatering Centrifuge liner Sefar gluten belt Belt profile for rotary drum vacuum ...

will contain approximately 12% wet milling industry is more complex and the corn kernel is divided into more components for higher value marketing. For example, the oil is extracted and sold in the wet milling industry as is the corn gluten meal, a protein supplement that contains a large amount of bypass protein, or UIP,

1. Introduction. Conventional wet milling of corn is a process designed for the recovery and purification of starch and several coproducts. The US corn wet milling industry can trace its beginnings back to 1844 when Thomas Kingsford, working at Wm. Colgate Company in Jersey City, NJ, convinced his employer to try a new alkali process for extracting starch from corn.

WesTech drum filters are available with drums up to ft in diameter and 36 ft in length and are built to customer specifications. Rotary Vacuum Drum Filter Designs Include: Scraper Discharge is the most common drum filter discharge. After dewatering, the cake is removed from the filter cloth by a scraper blade just prior to the re ...

The high fructose corn syrup and the corn syrup refineries together process approximately 161,000 lbs. of corn starch per hour. The purpose of the second process was added to transform a gluten/water slurry into a moist gluten cake. This was accomplished by using six rotary drum filters connected to .

This is usually accomplished economically on a rotary drum filter with belt discharge. DorrOliver Eimco EBelt Drum Filter DorrOliver Eimco EBelt Drum Filters for corn wet milling applications have been adapted to meet the industry''s specific needs for corrosion resistance and sanitation.

WhatsApp)

WhatsApp)