Ball Milling Method YouTube

Apr 01, 2016· Watch this video to learn about Ball Milling Method To learn more register at

WhatsApp)

WhatsApp)

Apr 01, 2016· Watch this video to learn about Ball Milling Method To learn more register at

Method of balls rolling on ball rolling mills is one of the most modern production methods. Transversal rolling of balls from the round billet is economical. It differs from other methods due to the possibility to produce grinding balls on the uninterrupted automated aggregates, which allows 2 to 8 times to increase the output and 1015% to ...

Ball Mill,Cone Ball Mills,Cement Ball Mill,EnergySaving Ball . We can supply any type of ball mill . Magnetic Separating Process; . Henan Bailing Machinery Co.,Ltd. is a modern enterprise specialized in manufacturing .

manufacturing method of ball mill. AS a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete stone crushing plant.

Manufacturing Method Of Ball Mill. A combination method of the theory and experiment in,ball mill manufacturer, ball mill grinder, ball mill price,ball mill manufacturers,ball mill,calculation of ball mill grinding efficiency,casting ball in cement mill manufacturers,china,chapter 9 manufacturing,china casting steel girth gear cement ball mill part,china girth gear used for ball ...

Jun 20, 2015· The only assumptions required for determination of the single ball trajectory are a coefficient of friction between the ball and mill lining, and unobstructed free fall after movement away from ...

With more than 100 years of experience in ball mill technology, ''s ball mills are designed for long life and minimum maintenance. They grind ores and other materials typically to 35 mesh or finer in a variety of applications, both in open or closed circuits.

All Grinding Mill Ball Mill Manufacturers understand the object of the grinding process is a mechanical reduction in size of crushable material. Grinding can be undertaken in many ways. The most common way for high capacity industrial purposes is to use a tumbling charge of grinding media in a rotating cylinder or drum.

It is a ball milling process where a powder mixture placed in the ball mill is subjected to highenergy collision from the balls. This process was developed by Benjamin and his coworkers at the International Nickel Company in the late of 1960.

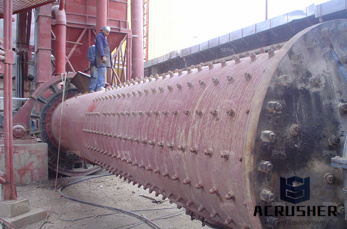

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles and stainless steel balls.

Jul 20, 2019· A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 50% of the mill volume and its size depends on the feed and mill size.

IQS Directory implements a thorough list of ball mill manufacturers and suppliers. Utilize our listing to examine and sort top ball mill manufacturers with previews of ads and detailed descriptions of each product. Any ball mill company can design, engineer, and manufacture ball mills to meet your companies specific qualifications.

The CIA Method 97 Improving the CIA Method 98 Optimizing the CIA Method 99 Chapter 8 Milling Methods 101 Introduction 101 Stamp Mills 101 Ball Mills 101 Wheel Mills 102 Jet Mills 104 Small Scale Techniques 104 Motorized Pestles and Mortars 104 Coffee Grinders 105 Blenders 105 Tumblers 105 Ring and Puck Pulverizers 105 Small Ball Mills 106 ...

Design Method of Ball Mill by Discrete Element Method The grinding rate of gibbsite in tumbling and rocking ball mills using fins was well correlated with the specific impact energy of the balls calculated from Discrete Element Method simulation. This relationship was successfully used for the scaleup of a rocking ball mill, and the optimum ...

Ball mill Wikipedia, the free encyclopedia A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, . Ball mills are also used in pyrotechnics and the manufacture of black powder, but cannot be used in the preparation. Ball mill for tile manufacturing Feb 13, 2016 ...

[Show full abstract] process responses to model the ball mill grinding based on BoxBhenken design method using DX software. Ball size, grinding time and solid content of ball mill were selected ...

Orbis Machinery, LLC is an independent, ownermanaged design, engineering and manufacturing company of process equipment. With nearly 60 years of combined process and engineering knowledge, Orbis Machinery specializes in double arm mixers, tumble and ribbon blenders, ball mills and rolling mill solutions for the process industry.

ball mill for tile manufacturing. Batching is the initial step in the tile manufacturing process The raw materials are taken in a ball mill and them grinded with water for certain hours The grinding media is usually alumina because it has good wear resistance and good density This process is .

As the developer and manufacturer of industryleading particle size reduction equipment, including Attritors (internally agitated ball mills) and DMQX horizontal media mills, Union Process is uniquely positioned to help you identify and source the correct grinding media for your application.

Abstract: Based on the research on the grinding media motion in the ball mill, the discrete equation of grinding media motion about ball mill is established and the motion regimes of grinding media is simulated using the discrete element method (DEM) with simplifying the contact model of grinding media and rock material.

Aug 19, 2018· Machining Process Manufacturing Process . Types of Milling Cutters Used in Machining Process August 19, 2018 October 2, 2019 Pankaj Mishra 1 Comment. ... Ball Mill Cutter. Ball cutters are also famous as ball nosed cutters. You can be easily identified as ball cutters as their end is hemispherical in shape. Ball cutters are used to decrease the ...

In the cement manufacturing process, each producing 1 tons of cement grinding material at least 3 tons (including fuel, clinker, gypsum, mixture and all kinds of raw materials), according to statistics, dry process cement production line grinding operation requires more than the consumption of power plant power accounts for about 60%, the raw ...

The operating principle of the ball mill consists of following steps. In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media. The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls.

Every ball passes through exacting inspections that automatically detect and remove offspec balls. A significant number of random samples is tested for hardness and examined microscopically for structure and finish. Only when we know that customers will be satisfied do we impart the Abbott Ball name to .

WhatsApp)

WhatsApp)