Vertical grinding mill types for cement plants YouTube

Sep 07, 2016· This video is unavailable. Watch Queue Queue. Watch Queue Queue

WhatsApp)

WhatsApp)

Sep 07, 2016· This video is unavailable. Watch Queue Queue. Watch Queue Queue

Designed for economically grinding a variety of cement types, this roller mill is much more than OK. OK Vertical Roller Mill_FLzenith ... combines the drying, grinding and separation processes into just one unit, which simplifies the plant layout. Read More

Coal Mills for Cement Plants. ... LOESCHE Awarded Order for Cement Plant in Nepal. LOESCHE has been able to convince the cement division of the Chaudhary Group (CG Group) of the advantages of its vertical roller mill technology. LOESCHE has managed to gain a new customer in Nepal, namely the cement division of the Chaudhary Group based in ...

vertical roller mills in cement plant vertical roller mill for cement plant vertical grinding mill for cement plant GGBS Vertical Roller Mill Cement and Mining GGBS vertical mill is the equipment to grind Ground Granulated Blast furnace Slag (GGBS),Nickel slag, slag manganese and so on into small particles. Get Price

Vertical roller mill for cement grinding plant Vertical roller mills present a compact and efficient grinding method. Clinker and gypsum is ground on a rotating table that passes under large rollers. Material is forced off the table by centrifugal force, where it is then swept up into an airstream to a classifier immediately above.

Sep 24, 2019· vertical roller mill is one of common cement plant use machines can be used in minerals grinding and mixing, Clirik new technology CLUM vertical roller mill can be used in cement plant.

Maintenance of Cement plant vertical roller mill wear parts News Date: 13:30:38. The cement vertical roller mill design allows the option of rotating the roller segments 180 degrees before replacing. They can also be hardfaced in place with a standard rewelding procedure.

Cement Vertical Roller Mill Great Wall Machinery. Great Wall Company''''s cement vertical roller mill in the production of cement specific surface area up to 3800 cm²/ g .

The FL vertical roller mill (VRM) was chosen to produce a full range of cement types at the Muktarpur Plant. Driven by two MW FL MAAG Max Drive gear systems, the impressive mill is the biggest VRM ever to be installed in a cement plant in .

Vertical Roller Mill for large scale cement plant SBM ... Vertical Roller Mill is a new kind of large scale power mill which is designed specially to solve the problems of low capacity and high consumption of industry mills.

2. Reducing the power consumption of cement clinker preparation effectively. According to the display of pulverized coal measured data, it can be saving electricity above 30% use of vertical roller mill production per ton cement clinker than traditional tube mill, and .

Grinding of cement clinker in vertical roller mills is a technology introduced by LOESCHE which was first used in 1935. Almost 30 years ago LOESCHE introduced the first vertical roller mill to grind both, cement clinker and granulated blast furnace slag, in one process.

Optimization of cement grinding using standard bond grinding calculations based on population balance models is successfully applied [4, 38]. Various grinding laws, energy relationships, control factors and controller design for cement grinding are discussed in [37]. Figure1. Vertical roller mill .

vertical Roller mill | LNV Technology Pvt. Ltd. Vertical roller mills are large grinding machines developed, designed and manufactured by ... A vertical cement mill is used for the finishgrinding of cement. ... A vertical raw mill is mainly used in cement plants for raw material grinding. Get Price

Thailand: Siam Cement has ordered a LM +3 CS vertical roller mill from Loesche for its cement plant in Kaeng Khoi. The mill will produce mediumfine cement qualities and is designed for grinding clinker, gypsum and limestone. The cement producer previously ordered a LM +3 CS mill from Loesche for its Ta Luang cement plant in 2014.

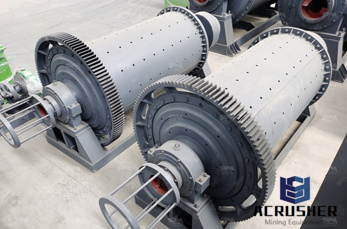

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

May 28, 2018· LOESCHE supplies four vertical roller mills (VRM) for cement plants of Pakistan''s second largest producer. Loesche | May 28, ... China, specialised in the design of cement plants.

Cement Vertical roller mill (VRM) is mainly used to grind cement clinker into fine powder during cement production, which can also be used to grind various materials such as calcite, marble, limestone, coarse whiting, talc, barite and dolomite etc. Application : Cement Plant, Cl

• Roller press in semi finish and finish grinding mode • Vertical roller mill (VRM) • Ring roller mill or Horo mill Even though there are various types of systems available for cement grinding, ball mills are predominantly used machines for cement grinding in large number of cement plants. In this paper authors are covering the process

Energyefficient grinding mill designed for a variety of cement types. Designed for economically grinding a variety of cement types, this roller mill is much more than OK. OK Vertical Roller Mill_FLzenith ... combines the drying, grinding and separation processes into just one unit, which simplifies the plant layout. Read More

Vertical Roller Mill Working Principle. There are many different forms of vertical mill, but the working principle is basically the same. All these forms of vertical roller mill with the grinding roller (or the equivalent of grinding roller grinding parts), grinding roll along the horizontal circular motion on the disc, the vertical pressure exerted on the grinding roller through the outer ...

Vertical Mill for Cement Plant, Clinker Grinding YouTube. Sep 04, 2013 · Vertical Roller Mill is a new type of grinding mill based on years concentrated design and development by introducing advanced European technology.

Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, cements and ceramics. It is an energy efficient alternative for a ball mill. Overview. Vertical roller mill is a kind of grinding machine for cement raw material, cement clinker, slag and coal ...

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

WhatsApp)

WhatsApp)