Safety on Milling Machines | Smithy Detroit Machine Tools

Milling machines require special safety precautions while being used. These are in addition to those safety precautions described in Chapter 1. Do not make contact with the revolving cutter.

WhatsApp)

WhatsApp)

Milling machines require special safety precautions while being used. These are in addition to those safety precautions described in Chapter 1. Do not make contact with the revolving cutter.

Every VF Series vertical machining center provides outstanding features at an excellent price, and features a wide range of available options to customize your machine to your exact needs. All Haas machines are designed and built in Oxnard, California, USA.

Here you find a collection of good to have milling formulas and definitions that are used when it comes to the milling process, milling cutters, milling techniques and more. Knowing how to calculate correct cutting speed, feed per tooth or metal removal rate is crucial for good results in any milling operation.

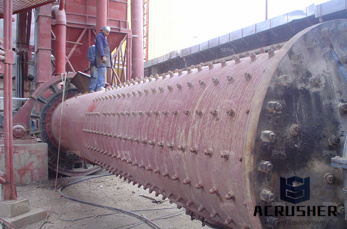

Cement mill vertical mill data bizzycarhirecoza. Vertical roller mill for raw Application p rocess materials Vertical roller mills are adopted in 20 cement plants 44 mills in Japan Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimation About 14million US [Newlybuilt] and about 230 million US [retrofitted], including the cost of supplemental ...

Vertical roller mill for raw Application p rocess materials. Fig2 Schematic process flow of vertical roller mill for grinding of raw materials Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimation About 14million US [Newlybuilt] and about 230 million US [retrofitted ...

Stirred Mills have been proven to provide energy savings compared with traditional ball mills. The finer the product required, the more efficient stirred mills will be than a ball mill. The attrition grinding action, vertical arrangement, and the finer media size distribution contribute to make stirred mills more energy efficient grinding machines.

New and Used LAGUN We have 23 listings for LAGUN listed below. Find items by using the following search options. You can also click on the column heading to sort through the listings. For more information on an item, contact the seller directly.

separator vertical mill formula of power g2educationin. separator vertical mill formula of power Our products are sold to 130 countries, being equipments in global crushing and grinding industry With the development of . Inquiry; separator motor for ok vertical mill lifetolifein.

buggenum loesche mills power consumption Grinding Mill China Mining Equipment Crushing Plant Processing Plant Contact About the companyHome»Mining Equipment»buggenum loesche mills power consumption Crushi...

Vertical milling machine is suitable for many operations: conventional milling, compound angle milling, drilling, jig boring and more. Perfect for technical schools, small parts production, tool rooms, and maintenance shops. Precision machined and ground table. Heavy duty cast iron base and frame. 220V plug not included. Head tilts 45° left or ...

Vertical roller mill is a kind of grinding machine for cement raw material, cement clinker, slag and coal slag. It has the features of simple structure, low cost of manufacture and use. Vertical roller mill has many different forms, but it works basically the same.

cement mill power consumption . specific power consumption in cement mill. Mill,Vertical Roller Mill,Double Rollers Crusher,Crusher Plant Usage and Appliion The vertical roller mill is widely used ...

Calculate the horsepower required for a milling operation based on the feed rate and depth of cut, which are used to determine the material removal rate (or metal removal rate). Also required is the unit power, which is a material property describing the amount of power required to cut that material.

Used Vertical CNC Mill for sale (79) currently in stock Brand New Vertical CNC Mill for sale (22) currently in stock. View Machines Are the top of the line. CNC Mills or Machining Centers are Computer Numerical Controlled and can vastly speed production and set up time.

Optimization of Cement Grinding Operation in Ball Mills Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and clinker pregrinders with...

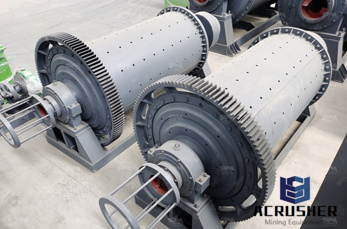

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ''chunk size'', product size as P80 and maximum and finally the type of circuit open/closed ...

specific power of vertical cement mill. Cement mill Wikipedia, the free encyclopedia, A cement mill (or finish mill in, Most cement is currently ground in ball mills and also vertical roller, cement milling is the largest user of electric power, Go to Product Center .

CNC Machine Tool Solutions. 3axis, 5Axis CNC Mills and Lathes. Your expertise paired with our CNC control technology—that''s mind over metal. That''s Hurco. Sign In Absolutely the best value on the market for small CNC machines. The VM series of 3axis machining centers features a small footprint with a large work cube. ...

We have supplied vertical roller mills (VRM) for raw, coal, slag and cement grinding for several decades. The vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding of raw materials. It is increasingly used as a solution for efficient grinding.

Contacts page classic with contact form in HTML. specific power cement plant vertical mill. We sincerely welcome you to contact us through hotlines and other instant communication ways.

May 23, 2014· Vertical vs. Horizontal Milling. Posted May 23, 2014 by CNC Masters filed under Machine Milling Vertical.. Even with all the power and versatility of modern milling machines, no single machine can handle everything – nor should it.

Feb 10, 2016· re VRM vs Ball Mill for Cement Grinding. Specific power consumption high for ball mill and Low for VRM ; Maintenance costs high for VRM and low for Ball mill ; Process control/process technology ball is operation friendlt and simple in operation but VRM requires some PID or .

Specific Power For Vertcal Mills ROLLER MILLS byLoesche is launching its new LMMaster for advanced vertical roller millreduce specific power (mill fan and mill table). SugarEquipment SizingSugar Engineers In the histograms below the vertical axis shows the relative frequency with which the parameter in question ...

cement international Gebr. Pfeiffer SE. Operational experience from India''''s first MVR vertical roller mill for cement ... The newly developed MVR roller mill for grinding cement raw material, cement .... jectrelated data, specific power consumption, gas vol ume requirements and...

WhatsApp)

WhatsApp)