Grinding down energy consumption in comminution .

Jun 21, 2019· Grinding down energy consumption in comminution ... put this into perspective in a 2017 report detailing his outlook for the mineral processing sector over five .

WhatsApp)

WhatsApp)

Jun 21, 2019· Grinding down energy consumption in comminution ... put this into perspective in a 2017 report detailing his outlook for the mineral processing sector over five .

Silica sand is a viable alternative for steel shot in fine grinding of coal. In addition to the low costs of silica sand, there are also the benefits of low specific energy consumption and wear associated with the use of silica sand. However, the unit capacity of a mill may be reduced slightly when silica sand is used as a substitute for steel ...

Patent US Grinding method Google Patents Jul 22, 2014 . Grinding is a key process in mineral ore dressing and in particle processing . In Shi, F., ''Comparison of grinding mediaCylpebs versus balls'', Minerals .. the rodshaped particles are formed from zirconia in whole or in part. Energy Use of Fine Grinding in Mineral Processing .

Fine grinding using stirred milling is becoming more common in the mineral processing industry. Fine grinding allows liberation of the valuable mineral, which leads to higher mineral recoveries in the process plant. The success of a fine grinding project can be strongly influenced by the energy efficiency, wear part consumption rate and ...

Aug 21, 2013· Mineral Processing. Mineral processing includes the mining, beneficiation, and separation of rare earth. Although all rare earth minerals are generally openpit mined, the energy requirement for crushing and grinding varies depending on their hardness and the gangue minerals .

Energy Use of Fine Grinding in Mineral Processing Springer Link. Dec 18, 2013 ... Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as .

The primarily used equipment in crushing arejaw crushers, gyratory crushers and cone crushers whereas rod mills and ball mills, closed circuited with a classifier unit, are generally employed for grinding purposes in a mineral processing plant. Crushing is a dry process whereas grinding is generally performed wet and hence is more energy ...

In a benchmark for energy consumption in comminution for the processing of copper and gold ores in Australia, Ballantyne et al. (Ballantyne and Powell, 2014) reported an average value of MW ...

However, most of the technical innovations, such as the increasing use of solventextraction, ionexchange etc., have been in the field of chemical ore processing, and, apart from the use of computers and ever larger unit process machines, there have been few major evolutionary changes in the field of physical mineral processing, where ...

Dec 18, 2013· F ine grinding is becoming an increasingly common unit operation in mineral processing. While fine grinding can liberate ores that would otherwise be considered untreatable, it can entail high costs in terms of energy consumption and media use.

It subsequently describes key mineral resource exploitation methods (open pit and underground mining) and the mineral processing required to obtain saleable products (crushing, grinding, sizing, ore separation, and concentrate dewatering, also with some text devoted to tailings dams).

Mar 01, 2014· Help us understand how you use this page by answering three quick questions. ... Energy Use of Fine Grinding in Mineral Processing. Jan de Bakker Pages 819. Download PDF (1232KB) View Article ... Springer for Research Development

May 15, 2014· For efficient use of energy in grinding – particles should form a coating on the liners and the grinding media. pulp should be fluid enough for steady flow through the mill. Thin pulp Solids settle, centrifuging occurs, coating on the grinding media is not possible improper grinding .

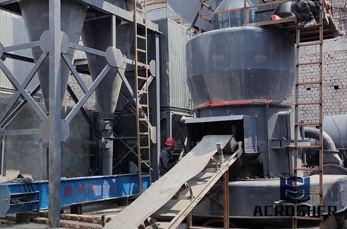

HCH ultrafine grinding mill is especially suitable for ultra fine grinding. After a long period of market application practice and user authentication, the device HC1395 model was certified by the China Association of calcium carbonate for energysaving equipment in China''s calcium carbonate ultrafine processing industry.

Advanced Control and Supervision of Mineral Processing Plants describes the use of dynamic models of mineral processing equipment in the design of control, data reconciliation and softsensing schemes; through examples, it illustrates tools integrating simulation and control system design for

Microbiol Mol Biol Rev 61:47–6. Neural netbased softsensor for dynamic particle size estimation in grinding circuits. Int J. Energy Use of Fine Grinding in Mineral Processing Springer. Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as mine. Mineral Processing Circuits: Their Operation and Optimisation.

Summary: In the oreprocessing sector, ball mills are increasingly being replaced by more energyefficient grinding processes. This trend commenced in the regrinding of flotation products, progressed into the tertiary grinding stage and is now also changing the technology of secondary grinding.

Journal description. The Open Mineral Processing Journal, an Open Access online journal, publishes original research articles, letters and reviews in all areas of mineral processing and extractive ...

Oct 17, 2018· Tumbling mills account major share of power consumption in mineral processing industries. In this paper, an attempt is made to minimize the power consumption in continuous grinding of chromite overburden by improving the grinding performance with different chemical additives. The additives taken are calcium chloride, sodium hexametaphosphate, sodium hydroxide and sodium .

Energy trend: Advances in fine grinding and classification ... stirred mills over ball mills in fine grinding can be extended to coarse grinding applications. ... of mineral processing for ...

Dec 18, 2013· F ine grinding is becoming an increasingly common unit operation in mineral processing. While fine grinding can liberate ores that would otherwise be considered untreatable, it can entail high costs in terms of energy consumption and media use.

Grinding Media Grinding media are the means used to crush or grind material in a mill It comes in different forms such as alumina oxide balls ceramic cylinders or soda lime glass At Norstone Inc we offer all types of medias used for grinding deagglomeration polishing deburring fillers proppants spacers refractory beds and shot peening. Get Price

Energy Use of Fine Grinding in Mineral Processing Springer 1 Mar 2014 ... The stirred mills used to perform fine grinding have additional process benefits, such as polishing the mineral .

Energy Use of Fine Grinding in Mineral Processing Fine grinding, to P80 sizes as low as 7 lm, is becoming increasingly important as mines treat ores with smaller liberation sizes. This grinding is typically done using stirred mills such as the Isamill or Stirred Media Detritor.

WhatsApp)

WhatsApp)