6lb Ball Mill | Black Powder Ball Mill 6 Pound

Dec 11, 2015· 6lb Black Powder Ball Mill Heavy duty rubber drum is sparkproof and leakproof. 110v,

WhatsApp)

WhatsApp)

Dec 11, 2015· 6lb Black Powder Ball Mill Heavy duty rubber drum is sparkproof and leakproof. 110v,

Home Page > Powder Slurry Mill / Mixer MTI has been manufacturing laboratory mill/mixer since 1994, offered the first model of ball mill into the world. Then the following years we''ve been devoting ourselves to designing the most efficient, practical and affordable laboratory mill/mixer. Thus ...

Ball mills are used in chemistry and in industry to grind hard solids to a very fine powder. They are very similar to rock tumblers. Basically, the idea is to rotate a container filled with heavy metal balls that crush the substance that you want to grind. Ball mills can be used to grind ceramic material, crystalline compounds, and even some ...

Lloyds''s book is the most complete and practical resource I know for information on ball milling theory and for plans to actually build your own ball mill. Here''s a shot of a nice, doublebarrel mill I built based on his principles. Homemade DoubleBarrel Ball Mill Ball milling replaces potentially unsafe hand grinding of chemicals and ...

The standard formulation for black powder is: 75 parts potassium nitrate, 15 parts charcoal and 10 parts sulfur (as always, all parts are by weight). You can find these chemicals at Which method to use. There are two methods to make BP: The ball mill method and the precipitation (or ''CIA'') method. You''ll need a ball mill in ...

Ball mills media. Product Compare (0) Show: ... Ball mill 1/2 inch Chrome Plated Steel grinding media X 50 pcs. ... Ball mill 15 Lb. 15 lb capacity high speed ball mill. Larger size for the more serious hobbyist to mill black powder,.. Add to Cart. Add to Wish List. Compare this Product. Ball mill 3 Lb capacity. 3 # lb capacity media ...

Opening the ball mill box reveals a user''s manual, a mill base, two mill jars, and five extra drive belts. Unpacking the Ball Mill The ball mill jars The first thing that struck me when I first looked at these mills was the nice quality of the mill jars. These things are really heavyduty, and have a very solid closing and sealinglid assembly.

offers 12,214 powder ball mill products. About 54% of these are mine mill, 30% are grinding equipment, and 1% are other fabrication services. A wide variety of powder ball mill options are available to you, such as ac motor, dc motor, and stepper motor.

Service Provider of Ball Mill Ball Mill For Powder Making offered by Geneva Design Solutions, Pune, Marashtra. Service Provider of Ball Mill Ball Mill For Powder Making offered by Geneva Design Solutions, Pune, Marashtra. IndiaMART. Get Best Price. Help. Call Us on ;

Ceramic Ball mill [ Capacity ]: –90 t/h [ Applicable Material ]: Dry ball mill is an important equipment to grind materials which is widely used in powder making production line including cement, feldspar, gypsum, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glass ceramics, etc.

This mill is going to come in really handy for lots of future projects. I hope this page gives helpful ideas to anyone in need of a ball mill. They are quick, easy, and cheap to build yourself. I need to add a disclaimer here for anyone thinking of using this sort of ball mill for milling gunpowder or other flammable or explosive powders.

Ball mills are also used for the particle size reduction of black powder, cement, fertilizer, silicates and even a variety of ferrous and nonferrous metals. Ball mills are very similar in design and operating concept to rock tumblers, which used milling media to polish rocks in a rotating cylinder.

New and Used Ball Mills for Sale Savona Equipment is a new and used Ball Mill supplier ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 50% of the mill volume and its size depends on the feed and mill size.

Ball Mill For Sale. The ball mill is a kind of equipment for grinding limestone. It mainly grinds the crushed material. The use of a ball mill to produce limestone powder not only reduces the cost, but also has less environmental pollution and can create high profits for the enterprise.

Everything you need to make your own black powder!Instructions are provided with this project. Black Powder Pyro Direct Online Store Home About Us My Account International Customers Contact Us

Apr 07, 2011· How to Make a Ball Mill. Ball mills are a special instrument used to break up hard solids into a fine powder. They are similar to rock tumblers in that the instrument is a rotating container filled with heavy balls to grind the substance...

Home Page > Powder Slurry Mill / Mixer MTI has been manufacturing laboratory mill/mixer since 1994, offered the first model of ball mill into the world. Then the following years we''ve been devoting ourselves to designing the most efficient, practical and affordable laboratory mill/mixer. Thus ...

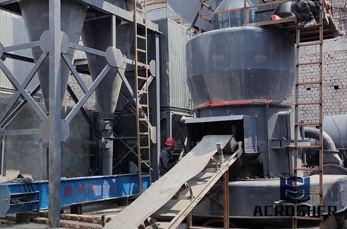

JoyalGrinding Mill,Fine Grinding Mill,Micro Powder Mill,Ultrafine Mill,Raymond Mill From China page is about the grinding mill,includes micro powder mill,high pressure mill,ygm model,raymond mill,3r,4r,5r,6r and ball mills,if you want to buy these joyal grinding mills.

Jul 26, 2017· Making aluminum powder with only some aluminum foil, the ball mill jar we built last video, and some steel balls! Perfect for use with thermite, tannerite, or flash powder, this process will ...

Best way to determine the balltopowder ratio in ballmilling? What is the best way to determine the balltopowder ratio for ballmilling a new material? ... The maximum power draw in ball mill ...

offers 12,216 ball mill for powder products. About 54% of these are mine mill, 30% are grinding equipment, and 1% are other fabrication services. A wide variety of ball mill for powder options are available to you, such as ac motor, dc motor, and stepper motor.

Ball mill is the key equipment for recrushing the materials after they are primarily crushed. Ball mill is widely used for the dry type or wet type grinding of all kinds of ores and other grindable materials in cement, silicate product, new building material, refractory, fertilizer, black and nonferrous metals, and glass ceramic industry.

Planetary Ball Mill has four ball grinding tanks installed on one turntable. When the turntable rotates, the tank axis makes planetary movements, the balls and samples inside the tanks are impacted strongly in high speed movement, and samples are eventually ground into powder. Various kinds of different materials can be ground by the mill .

WhatsApp)

WhatsApp)