Single Phase Planetary Concrete Grinder YouTube

Jun 04, 2012· DIY how to kill crabgrass. My crabgrass is not dying. How to prevent and control crabgrass Duration: 10:53. Pest and Lawn Ginja 1,191,951 views

WhatsApp)

WhatsApp)

Jun 04, 2012· DIY how to kill crabgrass. My crabgrass is not dying. How to prevent and control crabgrass Duration: 10:53. Pest and Lawn Ginja 1,191,951 views

Planetary Mills are ideally suited for fine grinding of hard, mediumhard, soft, brittle, tough and moist materials. The comminution of the material to be ground takes place primarily through the highenergy impact of grinding balls in rotating grinding bowls.

For this reason, LAVAL LAB offers a wide selection of highperformance mills, in various product groups, for every application and every specific need: Planetary Ball Mills, Ball Mills, Cutting and Beater Mills, Rotor Mills, Jaw Crushers, Roll Crushers, Cone Crushers, Disk Mills and Mortar Grinders.

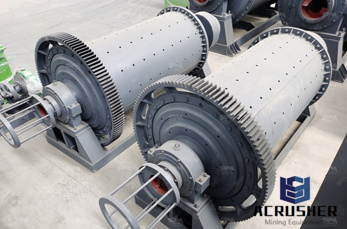

We offer high efficacy Planetary Ball Mill that is widely used for the grinding purposes of various materials such as cement, chemicals, ores, paints and so on. Our Cement Ball Mill can work continuously without any trouble. The internal cascading effects of our Alumina Ball Mill grind the material to the fine powder with high

Cement Mill Gear View Specifications Details Of Mill . Backed by skilled team of professionals we are engaged in manufacturing and supplying of supreme quality cement mill gear the offered gear finds wide usage in assembling machines due to its remarkable features like .

Furthermore, the shrouded ball mills are especially designed developed for powder distempers and cement and suppliers of industrial ball mill, shrouded ball mill used for dispersion of enamels and primers, powder distempers and cement paints. For dispersion of enamels and primers. Ranging from 25 Kg.

Used Ross Mixers. Ross is the leading worldwide manufacturer of specialty mixing, blending, dispersion and drying equipment. We have been in this business since 1842 and are the oldest and most reputable company in the world, with five plants operating in the United States, and four overseas.

Frequently asked questions Question: What is the minimal particle size that can be obtained during milling in the planetary mills used? Answer: The minimal particle size depends first of all on the material treated. Routine milling in planetary mills allows us to obtain submicron powders of the average particle size equal to several hundreds nanometers.

In industrial process engineering, mixing is a unit operation that involves manipulation of a heterogeneous physical system with the intent to make it more examples include pumping of the water in a swimming pool to homogenize the water temperature, and the stirring of pancake batter to eliminate lumps (deagglomeration). Mixing is performed to allow heat and/or mass ...

These are also known by the name of mill gears and apart from Sugar industry, also find usage in mills like steel rolling mills, cold hot rolling mills and others. Apart from manufacturing mill gears, we also hold expertise in providing turnkey solutions Sugar mills as well as associated industry sectors like: Cement Plants; Rolling mills

Concrete grinders can be characterized as planetary or rotary based on the configuration of the grinding stones or pads used at the base of the equipment. Understanding the difference between ...

With Industrial Mixers having a direct correlation to the perfomance, strength, and durability of final product, ROSS Planetary Mixers are ideal for ceramics, composites, glass, and metals. Learn More

industrial buildings, from the mediumvoltage supply to the outlet. Equipped with ... The Cement Industry is moving in a constant area of tension between ... A process automation system which optimizes mill process and electrical equipment with low energy consumption is essential. The raw meal is finally transported to the homog

Planetary Mill Gearbox. Planet and sun gears are manufactured from high alloy steel and heat treated for case carburizing to achieve optimum strength and wear resistance. Gear Profiles are ground to reduce noise level and optimized maximum root strength and minimum sliding contact to ensure high efficiency.

Jun 20, 2015· Safety in Cement Plant 3C ... or it may pass directly to the cement mill. The cement mill grinds the clinker to a fine powder. A small amount of gypsum a form of calcium sulfate is normally ground up with the clinker. The gypsum controls the setting properties of the cement when water is added. ... Industrial safety Anita Sharma. The ...

With the constant efforts for more then a decade, we are successfully catering to the need of various industries with our extensive range of grinding machines, grinding mills, emulsifier range includes attrition mills, ball mills, submersible basket mills, bead mills, pug mills, blending machines, ribbon blenders, sand mills, planetary mixers and others.

China Planetary Mill manufacturers Select 2019 high quality Planetary Mill products in best price from certified Chinese Grinding Mill manufacturers, Steel Mill .

Gearbox for Cement industry is the core of transmission equipment in cement production system,including reducer for vertical roller mill,reducer for central drive tube mill,reducer for side drive tube mill,gearbox for unilateral double tube mill,planetary gearbox for rolling press and planetary gearbox for central drive tube mill,supporting the use of vertical mill,tube mill and roller press.

Industrial planetary mill for cement is a new type of highefficiency nondeadpoint mixing equipment. It has a unique and novel mixing form. There are two or three multilayer paddle mills and one or two automatic scrapers in the container.

Vertical roller mills are widely accepted as the most efficient means for grinding cement raw material and ... planetary and a bevel stage (see also Section ). The disadvantages of this gearbox design at more ... industrial applications, with its great advantage of less material input at the same power. This design

It is revealed that the use of a varioplanetary mill allows to achieve the best results on grinding the powder building materials. 1. ... The purpose of this study was to determine the impact of various industrial grinders ... concrete, cementsand stone, cement stone (micro concrete), cementing agent, cementing substance ...

planetary cement mill working. Ball mill Wikipedia. A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing ... 1 Working; 2 Applications; 3 Description; 4 Advantages of the ball mill ... used in production lines for powders such as cement, silicates, refractory material, ... A planetary ball mill ...

A wide variety of industrial planetary ball mill options are available to you, There are 818 industrial planetary ball mill suppliers, mainly located in Asia. The top supplying countries or regions are China, Taiwan, China, and Malaysia, which supply 99%, 1%, and 1% of industrial planetary ball mill .

Cement; Crushing Grinding; Ball Mill Drives. We can provide all elements of a mill drive system as a fully optimised solution to suit your process exactly, or individual mill drive gearboxes, girth gears, pinions and couplings as required.

WhatsApp)

WhatsApp)