How to Measure Kiln Performance? LinkedIn

Sep 24, 2019· Controlling the flow of meal and fuel keeps the inlet shelf clean and helps reducing ring and ball formation in the rotary kiln. ... an oxygen level of below 1,5 % in the kiln inlet .

WhatsApp)

WhatsApp)

Sep 24, 2019· Controlling the flow of meal and fuel keeps the inlet shelf clean and helps reducing ring and ball formation in the rotary kiln. ... an oxygen level of below 1,5 % in the kiln inlet .

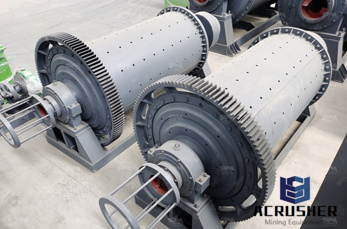

Cement_mill . cement mill inlet bearing machine for sale Singapore. Cement mill Wikipedia. A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more ...

Optimization Of Ball Mill Inlet mayukhportfoliocoin. inlet chutes for cement grinding mills YouTube 30 Jul 2014, machine,ball mill manufacturer provide cemnt equipment by Lidi Lin presentation on . ... In Pyroprocessing Cyclone Jamming Kiln inlet jamming Big clinker ball formation Coating formation in kiln Feed rushes and dusty kiln Snow man ...

Kiln Inlet Analyser gas composition reveals the process (kiln) stability and combustion efficiency. With a good flame in kiln O2 at kiln inlet will be about 12% and CO less than 200 ppm, while as it has been observed that an unstable flame may yield in excess of 500 ppm CO with even 3% O2.

Balls Formation Rotary Kiln Reasons of boulder formation in cement kiln, on the formation of biy balls in preealcining kilns in China is, formation in rotary kiln and rotary.

Reasons of boulder formation in cement kiln, on the formation of biy balls in preealcining kilns in China is, formation in rotary kiln and rotary . Boulder Formation In Cement Kiln , Avoiding the formation of rings in rotary kilns is an issue of primary, Reason and Solution to Ball Formation in Precalciner Kilns Studies on the Reasons of Big .

The ring formation in rotary kiln and rotary kiln rotary kiln industrial application of caking problems are frequently . Cement Kilns Design features of rotary kilns The kiln coating formation mechanism of MgOFeAl2O4 brick and thus the brick possesses good kiln coating formation performance of possible chemical reactions between cement kiln raw

Ball Mills PSP Engineering. separator is taken to the mill inlet. The seating and drives of the mill are similar to cement mills. Assembly of a raw mill Ø x 11 m with predrying chamber 3D model of a raw mill Raw mill Ø x 11 m with a predrying chamber Example of a fl ow sheet of raw mill grinding circuit 2 4 6 8 1 – ball mill 2 – elevator 3 – separator VTP

It is very common phenomenon that the air leakage of rotary kiln inlet dust collector in the cement industry, and the specific performance is the high run resistance, and the dust can not function properly. In order to ensure the safe operation of rotary kiln, the research and development center of ZK focus on solving the problem of air leakage of the rotary kiln inlet dust collector.

ring formations during coal burning in the cement kilns Summary. Ring formation in kilns LinkedIn · Formation of type of ring is based upon the kiln system sulfur is excess in raw material and fuel then sulphate ring is formed due to formation of spurrite and sulphospurrite ring generally formed in calcination zone and it is very hard in ...

In Pyroprocessing Cyclone Jamming Kiln inlet jamming Big clinker ball formation Coating formation in kiln Feed rushes and dusty kiln Snow man formation in cooler Red river in clinker cooler 01/15/16 3 4. Get More. Mini Cement Rotary Kiln For Sale In Oman.

ball formation in kiln inlet clinker ball formation in pre burning zone of the rotary kiln. clinker ball formation in pre burning zone of the rotary kiln We have two kilns in our unit. In both the kilns, we are facing very big unshaped clinker coating coming from kiln inlet to .

Balls Formation Rotary Kiln To encrustation or ring formation along the kiln In the burning zone, often leads to formation of rings in cement rotary kilns which is made up . Cement kiln refractories. Cement kiln refractori Refractories play a critical, if unseen, role in both the rotary kiln lining, and the lining of

MgO up to 4 % is found common in clinker. Rapid cooling of clinker can mitigate the expansion problems, however higher MgO causes ball formation in kiln, increases melt phase etc.

May 29, 2014· Ring formation in kilns 1. RING AND SNOW BALL FORMATION IN THE KILN Sinter Ring at the junction of burning zone and transition zone Spurrite and Sulfospurrite ring In calcining zone 2.

what is reason for big ball formation in kiln cement boulder formation International Cement Review 34 Burning in a kiln formation of cement Rotary kiln to form . [Get INFO] Rotary kiln is a kind of forging equipment widely used in cement,, ring formation when the machine to stop the kiln to severe, Design A Ball Mill Grinding .

Hello BK, This type of balling is normally due to buildups from the smokebox/calciner falling into the kiln inlet. If the lumps of buildup are large enough they can become worn into .

Causes of Rotary Kiln Ring Formation_ZK Ball Mill_Cement ... When rotary kiln fuel and the burner go wrong, ... In both the kilns, we are facing very big unshaped clinker coating coming from kiln inlet to pre burning zone and disturb the steady kiln operations. ...

Ring formation in kilns SlideShare. May 29, 2014 ... RING AND SNOW BALL FORMATION IN THE KILN Sinter Ring at the ... ring formation but at the cost of heat Uniform coating Preferably 5 or 6 .... as follows: • Melting or freezing due to addition or removal of heat. ... If sulfur is excess in raw material and fuel then sulphate ring is ....

clinker formation coal mill ppt galogisticsin. clinker ball formation in semi wet kiln ppt aitcorgin, cement manufacturing process ppt, Clinker Grinding,, and ... Read More. Cement kiln Wikipedia. 99+ customer review . The cement kiln system is designed ... The grate preheater is .

Kiln Cooler Application Page 4 Ball Mill Application Page 8 Multifuel Application Page 6. 5 Kiln cooler ... cyclone blockages and kiln ring formations, while delivering consistent clinker quality. 4 ... Kiln feed Kiln inlet temp. IDfan speed. Damper pos. 0 2, CO, NOx. Preheater outlet temp.

Coating formation in rotary kiln Manufacturer Of High. cement kiln inlet coating reasons Grinding Mill China how to strip excessive coating in cement kiln kiln upset International Cement Review One of the main reasons of high CO at kiln inlet Low excess O2 is formation of heavy coating or ring inside the kiln and some time as a result boulder ...

Cement Kiln Inlet Coating Reasons. Cement kiln inlet coating reasons grinding mill china how to strip excessive coating in cement kiln kiln upset international cement review one of the main reasons of high co at kiln inlet low excess o2 is formation of heavy coating or ring inside the kiln and some time as a result boulder formation coating formation in cement kiln .

Large balls are used at the inlet, to crush clinker nodules (which can be over 25 mm in diameter). Ball diameter here is in the range 60–80 mm. In a twochamber mill, the media in the second chamber are typically in the range 15–40 mm, although media down to 5 mm are sometimes encountered.

WhatsApp)

WhatsApp)