Improvements in gold ore cyanidation by preoxidation with ...

On the other hand, a high gold recovery was achieved for the biooxidated samples: after 24 h cyanidation gold dissolution reached about 91% results have shown the technical ...

WhatsApp)

WhatsApp)

On the other hand, a high gold recovery was achieved for the biooxidated samples: after 24 h cyanidation gold dissolution reached about 91% results have shown the technical ...

The InLine Leach Reactor – The New Art in Intensive Cyanidation of High Grade Centrifugal Gold Concentrates. "RANDOL GOLD AND SILVER FORUM, DENVER, MAY 1999" A H (Sandy) Gray Technical Director Nick Katsikaros Senior Process Engineer Gekko Systems Pty Ltd. 321 Learmonth Road, Ballarat, Victoria, 3350, Australia.

Jan 01, 2016· 3. Conclusions. The information in Table has been captured from the chapters in this book. It is not intended to be more than a summary reference to get a flavor of the processes that operating gold plants have implemented to overcome the issues pertaining to their particular ore mineralogy and water chemistry, and the many other sitespecific factors that .

Gold Extraction

It is an important part in the gold cyanidation process. Why . Inquire Now; Gold Electrolysis Process Gold Recovery Fill hydrogen peroxide H 2 O 2 40ml per 2000 ml melted gold chemical water. stir it together and wait for 5 minutes. You have to fill hydrogen peroxide H 2 O 2 in melted gold chemical water to destroy cyanide chemical structure.

Heap leaching is an industrial mining process used to extract precious metals, copper, uranium, and other compounds from ore using a series of chemical reactions that absorb specific minerals and reseparate them after their division from other earth materials. Similar to in situ mining, heap leach mining differs in that it places ore on a liner, then adds the chemicals via drip systems to .

Further, LeachAid allows anaerobic dissolution of gold, and thus allows the Consep Acacia to use heated leaching for even faster kinetics and more complete leaching. In 2011, an independent study conducted in Perth, Australia compared the Consep Acacia to a rival product, operating in a gravity gold circuit.

Dec 20, 2018· Cyanide Gold Extraction Methods. The existing cyanide gold plant in China''s gold mines basically adopts two types of gold extraction process, one is a socalled conventional cyanidation process for gold extraction by continuous countercurrent washing with a thickener, and the gold is replaced by zinc powder (CCD method and CCF).

Jun 01, 2003· A cyanidation study was conducted to determine the necessary retention time of the leach circuit and the optimal gold extraction and cyanide consumption. Results have shown that the gold leaching kinetics could be significantly improved by the addition 100–200 g/t lead nitrate directly in the grinding circuit, followed by a 6 h cyanidation.

Home; Products; cyanidation process in dolomite strong ability; cyanidation process in dolomite strong ability

The chemistry of cyanidation is proven and well known with the majority of gold operations in Australia using the process. Cyanidation as a process had been used for the extraction of gold since 1890. The reaction for the leaching of gold is known as .

Cyanidation of a pyrrhotitebearing gold ore G. Deschênes1*, D. Hall2 and M. Fulton1 1 Mining and Mineral Sciences Laboratories, CANMET, Natural Resources Canada, 555 Booth Street, Ottawa, Ontario, K1A 0G1 Canada 2 Placer Dome Canada, Musselwhite Mine, Box 7500,Thunder Bay, Ontario, P7B 6S8 Canada Received 30 July 2002; accepted 21 ...

Gold cyanidation (also known as the cyanide process or the MacArthurForrest process) is a hydrometallurgical technique for extracting gold from lowgrade ore by converting the gold to a watersoluble coordination is the most commonly used leaching process for gold extraction. [1] Production of reagents for mineral processing to recover gold, copper, zinc and .

Gold cyanidation (also known as the cyanide process or the MacArthurForrest process) is a metallurgical technique for extracting gold from lowgrade ore by converting the gold to a water soluble coordination is the most commonly used process for gold extraction. [1] Production of reagents for mineral processing to recover gold, copper, zinc and silver .

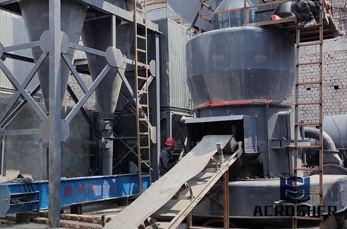

The gold cyanidation plant in Tanzania This is the gold cyanidation plant in Tanzania About 5 kilograms of gold have been produced here every month The plant had 4 partners Just about 30 days thereafter we were informed that only 3 partners left due to the fatal car accidentInquire Now; suppliers of gold desorption plants in china

of the gold lost in the final cyanidation residue. fications to the existing plant to improve the gold As desired by NML, three samples namely (1) runofrecovery, which at present was only about 90°%x. mine ore after tertiary crushing, (2) feed to cyanidation plant and (3) final cyanidation tailing were received Messrs P. V. Raman and P. 1. A.

Dec 20, 2018· Gold flotation. The Froth Flotation Method is means separating minerals according to their different physical and chemical properties. According to classification, the flotability of gold and silver minerals is included in the first category of natural and nonferrous heavy metal sulfides, characterized by low surface wettability and easy flotation, which can be .

LeachWELL 60X is a reagent grade catalyst formulated for fast cyanide leach gold assaying. When used with 5% cyanide the dissolution rate of gold, copper and silver is increased more than sixty fold. The leach rate for gold under appropriate conditions for example, .

Use Precipitating In A Sentence Precipitating. Dissolving the gold in potassium cyanide solution and then precipitating the metal 5. 0 Three stages in the process are to be distinguished i. calcination to convert all the metals except gold and silver into oxides which are unacted upon by chlorine ii. chlorinating the gold and lixiviating the product iii.

Summary of Gold Cyanidation Methods Miningpedia. Since the gold rush in the 1970s, gold mining has been popular all the time. With the depletion of easily separated gold resources, the modern gold extraction equipment and technology is developing towards the extraction of gold from refractory gold deposits.

On the other hand, a high gold recovery was achieved for the biooxidated samples: after 24 h cyanidation gold dissolution reached about 91% results have shown the .

called miniCIP, in Diwalwal, using sodium cyanide (NaCN) for leaching gold from milled and amalgamated ore. Gold loaded activated carbon being burned to ash in the center and an agitated tank for cyanidation in the drum below the roof to the right, behind waste and storing ponds. Photo: Lars Hylander. Figure 5.

Download Citation | Intensive cyanidation of gold from gravity concentrates ina drumtype apparatus | Gravimetric, chemical, and mineralogical analyses of a goldbearing gravity concentrate have ...

Inside the drum, the ore concentrates mix with a typically strong 12% cyanide solution and pure oxygen (in the case of gold extraction), known as intensive leaching. Specialised baffles inside the drum keep solids in constant contact with the chemical solution.

WhatsApp)

WhatsApp)