ball mill working principle YouTube

May 08, 2015· Great Wall ball grinding mill process ball grinding mill working principle 3D our website:, our email:salesgw...

WhatsApp)

WhatsApp)

May 08, 2015· Great Wall ball grinding mill process ball grinding mill working principle 3D our website:, our email:salesgw...

The Attritor is often referred to as a agitated ball mill. ... Wet Milling Attritor Continuous : Dry Milling Attritor Batch Cont. Recirculation Series ... How the Continuous Attritor Works The continuous mill has a compact vertical design suitable for continuous production of large quantities of materials. ...

The Super Orion ball mills are employed for the dry ultrafine grinding of mineral powders and ceramic raw materials. In combination with an air classifier, for example, ultrafine fillers at high outputs and simultaneously low specific energy inputs can be produced.

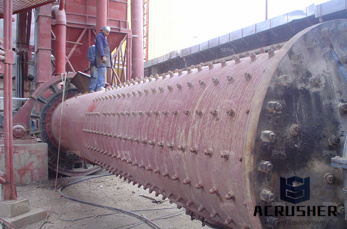

The ball mill is a typical material grinder machine which widely used in the mineral processing plant, ball mill performs well in different material conditions either wet type grinding or dry type, and to grind the ores to a fine size. Main ball mill components: cylinder, motor drive, grinding medium, shaft. The cylinder cavity is partial ...

Ball mill 1456А of continuous operation for dry material grinding. Ball mill 1456А is designed for dry grinding of ore and nonmetallic raw materials, construction materials of medium hardness. The mill belongs to the tube ball mills of continuous operation with central discharge of ground product.. The drum ball mill is used in oremining, mining and chemical and other .

The SD Dry Grinding Attritors can be operated in both continuous and batch processing applications. In the continuous operation, the material is fed into the vessel at the top. It then migrates through the agitating media bed where it is processed to a desired particle size and is discharged through metering bar grids at the bottom of the tank.

offers 401 dry grinding mills products. About 36% of these are mine mill, 14% are mills, and 5% are flour mill. A wide variety of dry grinding mills options are available to you, such as end mill, raymond mill, and ball mill.

3. Dy ball mill can be used for onepass grinding or closecircuit grinding that is composed of powder concentrator; 4. Overflow dry ball mill and grid dry ball mill can be selected according to the ore property and discharge way; 5. The output material after the dry grinding is the qualified material; 6.

Continuous Dry Grinding Ball Mills. Grinding Mills Free Online Library. a range of conical pebble mills 1 to 250 hp 0 to 187 kw are available, as are tricone ball mills for dry grinding sized from 600 to 1,750 hp 448 to 1,305 kw he vertimill, a vertical stirred media mill, can be used for efficient wet or dry fine grinding in continuous or batch applications.

High capacity with continuous grinding efficiency 5. Quality guarantee, safe operation, energysaving. The ball mill machine usually coordinates with other rock crusher machines, like jaw crusher, cone crusher, to reduce the ore particle into fine and superfine size. Ball mills grinding tasks can be done under dry or wet conditions.

Reliable and effective grinding mills includes being safe throughout. When the mills are quoted we make sure to include any and all safety components needed. Long life and minimum maintenance. To help you get the most of your business, we have designed our ball mills with longterm operation in mind with a minimum need for maintenance.

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of both ferrous and nonferrous metals. The ball mill can grind various ores and other materials either wet or dry.

Westpro''s versatile GRINDING MILLS are specially developed for a vast range of applications. Size reduction of various materials Wet or dry grinding Continuous or batch operation; Rod or ball mill Pebble mill; Lime slaking

Ball Mill Loading (dry milling) When charging a ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar use on a jar rolling mill it is important to have the correct amount of media and correct amount of product. Charging a Dry Mill – The general operation of a grinding mill is to have the product impacted between the balls as ...

Continuous Ball Mill Dry Grinding; Continuous Ball Mill Dry Grinding. Our company has been devoted to mining machinery for 40 years. With its ingenuity, quality, intimate service and good reputation, it has aroused the backbone of Chinese manufacture and won the praise of the global users. We also choose us as a successful enterprise and a ...

Good finegrinding effect, high production efficiency; Dry ball mill machine has the characteristics of strong adaptability to material, continuous production, easy adjustment of product''s fineness. Large capacity; The dry ball mill retains end cover structure form of ordinary mill, its large diameter inlet and outlet increase handling capacity.

Mineral Processing EPC. Xinhai EPC provides services of sample test, mine design, equipment manufacture, etc. for clients, and solves the common problems in plant construction such as budget overrun, schedule delays, unqualified equipment, unclear recovery benefit, disputes of the manufacturers, and unclear responsibility of aftersale service

Dry Grinding VS Wet Grinding. Previous Next ... Furthermore the throughput of a continuous feed mill is greater in wet grinding; probably due to the better flow properties of a pulp in comparison with a dry material. ... Effect of Particle Size Distribution on Grinding Rate in Dry Ball Milling. It has been shown above that: (i) the particle ...

In powder grinding plant, ball grinding process flow includes crushing, milling,air classifying,packing,silos,bucket elevator,conveying,etc. Grinded material discharges from outlet grit fluently. Ball grinding mill is Formed a closed system with air classifier.

continuous dry grinding ball mill are mainly grid ball to different materials size, you can choose the ball mill of proper length and diameter ratio,the end product can be controlled by the internal of dry type ball mill,there is ventilating device to increase the mobility of input Machine dry type ball mills have widely used in limestone,Granite ...

Continuous dry grinding ball mills india. Ball mill is an efficient tool for grinding many materials into fine powder The ball mill is used to grind many kinds of row are two ways of grinding the dry process and the wet can be divided into tubular type and flowing .

Simplified handling and continuous status visibility. Programming and handling of Anton Paar''s ball mill is simple. Only one encoder knob is required for quickly setting the time and frequency for your sample grinding and starting the homogenization procedure. The front display LEDs inform you about the status and the set parameters at all times.

PATTERSON Batchtype Ball Pebble Mills. PATTERSON''s Ball and Pebble Mills are ideally suited for wet or dry grinding processes, size reduction and dispersion, and deflocculation in solidliquid systems. Mill sizes range from 10 gal.

continuous ball mill dry grinding. AS a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete stone crushing plant.

WhatsApp)

WhatsApp)